Gehl RT175 RT210 RT250 RT175 RT210 Gen2 RT175 RT210 RT250 Gen3 Service Manual and Diagram 50940164C

Size: 19.98 MB

Language: English

Machine: Compact Track Loader

Machine Model: RT175 RT210 RT250 RT175 RT210 Gen2 RT175 RT210 RT250 Gen3

Part Number: 50940164C

Document: Service Manual, Electrical and Hydraulic Diagram

Publication Date: 2018

Pages: 440 Pages

The Bookmarks of Gehl RT175 RT210 RT250 RT175 RT210 Gen2 RT175 RT210 RT250 Gen3 Service and Diagram 50940164C:

Introduction

Safety Symbol

Contents and Use of this Manual

Safety Symbol and Signal Words

Machine Orientation

Proper Machine Use

Service and Registration

ROPS/FOPS Certification Label

Component Identification

Fields of Application

Using Attachments

Vibration Information

Fire Extinguisher

Manufacturer Information

Indicator and Operation Symbols

Safety

Safety Symbol and Signal Words

Mandatory Safety Shutdown Procedure

Before Starting

During Operation

Applications with Load-Handling Devices

Parking the Machine

Electrical Energy

Maintenance and Service Safety Practices

Battery Hazards

Fire Hazards

Additional Safety Equipment

Crystalline Silica Exposure

Transporting the Machine

Lifting the Machine with a Crane

Loading and Transporting the Machine

Safety Decals

ANSI-Style Safety Decals

ISO-Style Safety Decals

Specifications

Fluids/Lubricants Types and Capacities

Dimensions

Payloads/Capacities

Weights

Track Drive

Coolant Compound Table

Engine

Hydraulic System

Electrical System

Sound Power/Pressure Levels

Vibration Levels

Features

Standard Features

Optional Features

Common Materials and Densities

Controls

Multi-Function Display

Switches/Indicators

Multi-Function Display Screens

Control Joysticks

Straight Tracking Adjust

Parking Brake/Work Hydraulics Lock-out

Cab Heat and Air Conditioning (Option)

Operator’s Seat

Seat Belt

Armrest/Joystick Console Adjustment

Throttle Controls

Travel Controls

Travel Speed Range Selection

Lift Arm Float Button

Hydraglide™ Button (Option)

Work Lights

Battery Disconnect Switch (Option)

Windshield Wipers/Washer

Operation

Operational Checks

Before Operation

Starting the Engine

Warm Up

Run-In Period

Stopping the Engine

Engine Stalling

Diesel Particulate Filter (DPF) Regeneration Procedures

After Operation

Jump-Starting

Travel Drive Operation

Lift Arm Operation

Self-Leveling

Lift Arm Float

Hydraglide™ Ride Control System (Option)

Hydraulics Control Lock

Lift Arm Support

Connecting/Disconnecting Attachments

Powering Attachments with Hydraulic Function

Optional 14-Pin Connector

Lifting the Machine using a Crane

Loading and Transporting the Machine on a Transport Vehicle

Storage Box

Maintenance

Maintenance Schedule

Maintenance Interval

Engine Maintenance

DPF Service

Fuel System Maintenance

Hydraulic System Maintenance

Hydraulic Hose Maintenance

Travel Motor Maintenance

Track Maintenance

General Lubrication

Tilting ROPS/FOPS

Electrical System

Long-Term Storage

Air Conditioning Maintenance

Windshield Washer Reservoir

Final Shutdown / Decommissioning

Maintenance Log

Lift Arm and ROPS/FOPS

Lift Arm Alignment Stops

Tilt Stop Adjustment

Lift Arm Removal

Lift Arm Installation

ROPS/FOPS Service

ROPS/FOPS Removal

ROPS/FOPS Installation

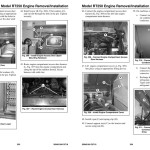

Model RT250 Engine Removal/ Installation

Engine Removal – Model RT250

Engine Installation – Model RT250

Models RT175/RT210 Tier 4 Engine Removal/Installation

Tier 4 Engine Removal Model RT175 (S/N 811001 and Up) Model RT210 (S/N 921001 and Up)

Tier 4 Engine Installation Model RT175 (S/N 811000 and Up) Model RT210 (S/N 921000 and Up)

RT175/RT210 interim Tier 4 Engine Removal/Installation

Interim Tier 4 Engine Removal Model RT175 (S/N 811000 and Before) Model RT210 (S/N 921000 and Before)

Interim Tier 4 Engine Installation Model RT175 (S/N 811000 and Before) Model RT210 (S/N 921000 and Before)

Hydraulic Equipment

General Hydraulic Service Notes

Hydraulic Oil Analysis

Hydraulic Control Valve

Hydraulic Pilot Valve

Self-Level Valve

Float/Hydraglide™ Valve

Travel Drive Motors

Hydrostatic Drive Pump

Hydrostatic Pump Swash Plates

Hydrostatic Pump Removal

Hydrostatic Pump Installation

Hydrostatic Pump Drive Coupling Removal and Installation

Hydrostatic Pump Input Shaft Seal Replacement

Hydraulic Gear Pump

Hydraulic Cylinder Disassembly/ Assembly

Hydraulic System Tests

Hydrostatic Pumps

Hydrostatic Drive System Pressures

Hydrostatic Charge Pressure Test and Adjustment

Main Relief Pressure Test

Main Pressure Adjustment

Tilt/Lift Cylinder Relief Pressure Tests

Cylinder Drift Tests

Cylinder Internal Leakage Tests

Electrical/Control Systems

Electrical Schematics

Battery

Power Distribution

Electrical Control System

CAN System Service/Computer Connection

Lighting

Electronics Diagnostic Kit

Diagnostic Kit Operation

Displayed Telemetry Information

Troubleshooting

Engine Troubleshooting

Indicator Lamp Troubleshooting

Seal and Hose Troubleshooting

Hydraulic System Troubleshooting

Hydrostatic Travel Drive System Troubleshooting

Hydrostatic Drive Motors Troubleshooting

Electrical Troubleshooting

Miscellaneous Troubleshooting

Error Codes

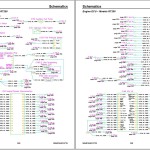

Schematics

Schematic Conventions

Model RT250 (SN 70501 and Up) Schematics

Model RT175 (Serial Numbers 811001 and Up) Model RT210 (Serial Numbers 921001 and Up)

Model RT175 with Tier 4 Engines (Serial Numbers 411051 and Up) Model RT210 with Tier 4 Engines (Serial Numbers 921651 and Up)

Model RT175 with interim Tier 4 Engines (Serial Numbers 811000 and Before) Model RT210 with interim Tier 4 Engines (Serial Numbers 921000 and Before)

Hydraulic Schematic

Index

#more Product: Gehl Operators Manual, Parts Catalog, Service Manual, Wiring Diagram