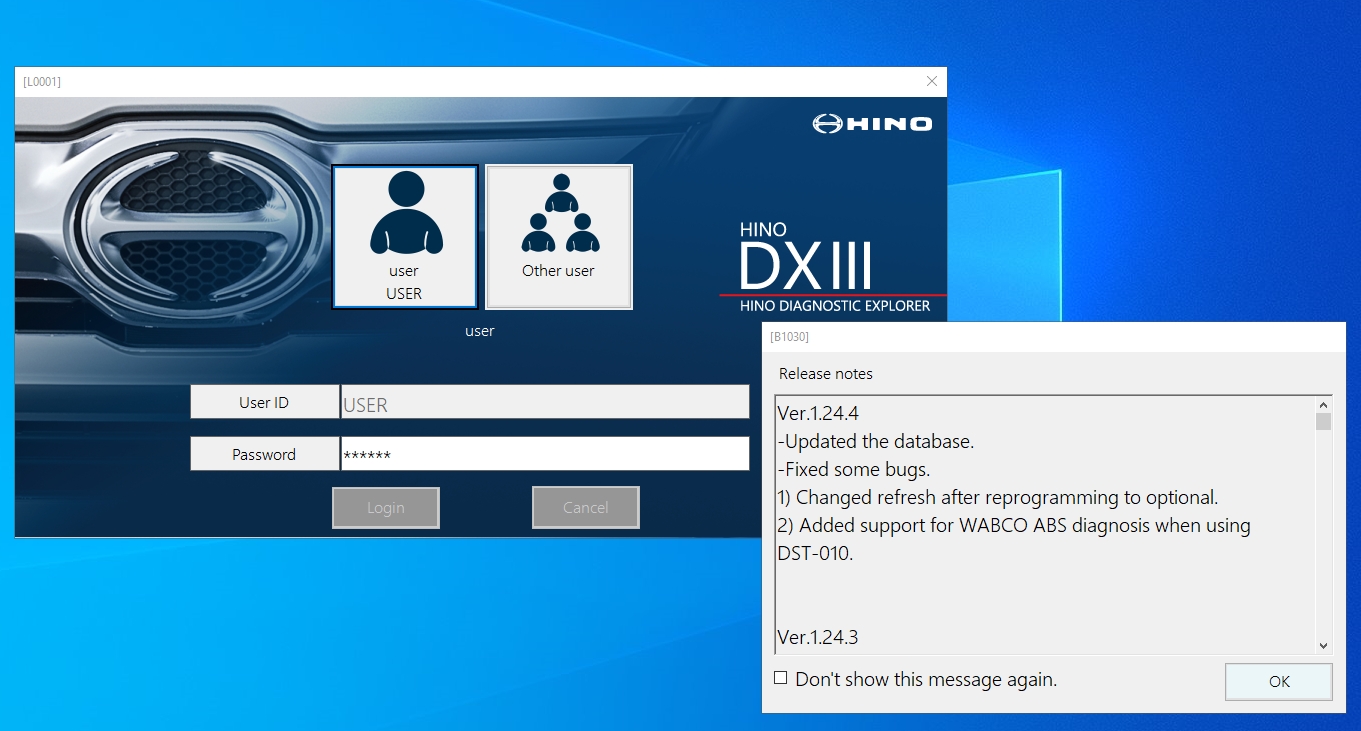

Hino Diagnostic Explorer 3 DXIII Ver.1.24.4 06.2024

Size: 605 MB

Software: Hino DXIII diagnostic program for trucks Hino

Machine: Truck

Interface Languages: Japanese, Chinese, Spanish, Thai, English, Russian, French, Indonesian,

Database Languages: Only English

Operating system: Windows 7, Windows 8, Windows 10 32 & 64 bit (Tested on Windows 10 Pro v1904)

Date: 06.2024

Version: Ver.1.24.4

Contact Us: “CLICK HERE”

Payment Method: “CLICK HERE”

Shopping Guide: “CLICK HERE”

CHANGELOG:

Ver.1.24.4

-Updated the database.

-Fixed some bugs.

1) Changed refresh after reprogramming to optional.

2) Added support for WABCO ABS diagnosis when using DST-010.

Ver.1.24.3

- Updated the database.

- Fixed some bugs.

1) When searching for diagnosis history on the GSPS side, some information is not displayed in the vehicle classification in the search results.

Ver.1.24.2

-Fixed some bugs.

Ver.1.24.1

-Updated the database.

-Fixed some bugs.

Ver.1.23.10

-Updated the database.

-Fixed some bugs.

Ver.1.23.9

-Updated the database.

-Fixed some bugs.

-Some devices that cannot be diagnosed by Denso's interface "DST-010" can now be supported.

Ver.1.23.8

-Updated the database.

-Fixed some bugs.

Ver.1.23.7

-Updated the database.

-Fixed some bugs.

-Implemented a function conforming to "Past work information" of Hino DXII.

Follow the steps below to check.

HOME screen - Special working - Past work information list

-Since the repro work after replacing the supply engine is different for the ECU direct engine and the non-direct engine, the explanation of each work content is described in the "Notes" column.

Ver.1.23.6

-Updated the database.

-Fixed some bugs.

Ver.1.23.5

-Updated the database.

-Fixed some bugs.

Ver.1.23.4

-Updated the database.

-Fixed some bugs.

-Vehicle reconnection prevention function has been implemented.

1) If the connection with the vehicle cannot be confirmed for a certain period of time during the diagnosis, a confirmation screen will appear prompting you to check the connection status of the connectors and cables.

After the confirmation screen is displayed, screen operations are restricted until the connection with the vehicle is confirmed.

*The connection is checked when operating the screen, and if it can be confirmed, the operation will be executed, and if it cannot be confirmed, the confirmation screen will be displayed again.

2) When checking the connection after the confirmation screen is displayed, if a connection to another vehicle is detected, a warning screen will be displayed and the diagnosis will end.

-When accessing GSPS from the HINO DXⅢ screen, it is no longer necessary to enter the ID/PW on the browser side. (Digital certificate selection is still required)

This function is only compatible with Microsoft Edge.

If you are using a browser other than Microsoft Edge, please switch to Microsoft Edge.

-The screen display when referring to the device information installed in the vehicle learned in the past has been changed.

Before) Confirm the connection of only the referenced device, and display only the referenced device on the system selection screen

After) Confirm the connection of only the referenced device, and display it on the system selection screen including other devices than the referenced device

-Implemented the installer manual download function. (in the "Other" function)

User can check the installer version update status at any time.

Ver.1.23.3

-Updated the database.

-Fixed some bugs.

-Active test can now be performed even when the data monitor item is selected and the data monitor is not being executed.

*To start the data monitor, it is necessary to end the active test once.

-System information and memo contents of the played file are now displayed on the data monitor playback screen.

Ver.1.23.2

-Updated the database.

-Fixed some bugs.

Ver.1.23.1

-Updated the database.

-Fixed some bugs.

-Added language support. (Vietnamese)

Ver.1.22.12

-Updated the database.

-Fixed some bugs.

Ver.1.22.11

-Fixed some bugs.

Ver.1.22.10

-Updated the database.

-Fixed some bugs.

Ver.1.22.9

-Updated the database.

-Fixed some bugs.

Ver.1.22.8

-Updated the database.

-Fixed some bugs.

Ver.1.22.7

-Updated the database.

-Fixed some bugs.

Ver.1.22.6

-Fixed a bug in the data transmission / reception function with the server.

Ver.1.22.5

-Function addition

A print function for timeline data (work history) has been added to "Special working".

Ver.1.22.4

-Updated the database.

Ver.1.22.3

-Updated the database.

Ver.1.22.2

-Updated the database.

Ver.1.22.1

-HINO DXⅢ has been released.

PRIMARY MODEL LIST:

700 series

600 series(Conventional)

500 series

300 series

Bus/Coach, Heavy

Bus/Coach, Medium

Bus/Coach, Light

Retro

Industrial Engine

Other

300 series(COE) (North America)

300 series (N engine)

300 series (J engine)

BUS

FC bus

Bus/Coach, Light(Liesse2)

200 series (GD engine)

DETAIL MODEL LIST:

Hino 700 series Japan KC/KL Diagnostic Solution

Hino 700 series Japan PK/KS Diagnostic Solution

Hino 700 series Japan ADG/BDG/BKG Diagnostic Solution

Hino 700 series Japan LDG/LKG/QKG/QDG Diagnostic Solution

Hino 700 series Japan 2DG/2KG/2PG/2RG/2SG Diagnostic Solution

Hino 700 series 国4/国5/国6 Diagnostic Solution

Hino 700 series EURO2/EURO3/EURO4 Diagnostic Solution

Hino 700 series EURO5 With VCS Diagnostic Solution

Hino 700 series EURO5 Without VCS Diagnostic Solution

Hino 700 series EURO6 Diagnostic Solution

Hino 700 series Global Diagnostic Solution

Hino 700 series Japan FC Diagnostic Solution

Hino 600 series(Conventional) Global Diagnostic Solution

Hino 600 series(Conventional) North America (-10MY) Diagnostic Solution

Hino 600 series(Conventional) North America (11-14MY) Diagnostic Solution

Hino 600 series(Conventional) North America (15-19MY) Diagnostic Solution

Hino 600 series(Conventional) North America (20MY) Diagnostic Solution

Hino 600 series(Conventional) North America (21MY) Diagnostic Solution

Hino 600 series(Conventional) North America (22MY-) Diagnostic Solution

Hino 500 series Japan KK Diagnostic Solution

Hino 500 series Japan PB/PK/KS/VF Diagnostic Solution

Hino 500 series Japan ADG/BDG/BJG/BKG Diagnostic Solution

Hino 500 series Japan LDG/LKG/SKG/SDG/SJG/TKG/TQG/QKG Diagnostic Solution

Hino 500 series Japan 2DG/2KG/2PG Diagnostic Solution

Hino 500 series EURO3/EURO4/EURO5 Without VCS Diagnostic Solution

Hino 500 series EURO3/EURO4/EURO5 With VCS Diagnostic Solution

Hino 500 series EURO6 Diagnostic Solution

Hino 500 series THAI CNG Diagnostic Solution

Hino 500 series Global Diagnostic Solution

Hino 500 series SRS 500k (Airbag) Diagnostic Solution

Hino 300 series Japan KK/PB/VF Diagnostic Solution

Hino 300 series Japan BDG/BKG/BJG/ABG/NBG Diagnostic Solution

Hino 300 series Japan SJG/SKG/SDG/TQG/TKG/TPG/TSG/TDG Diagnostic Solution

Hino 300 series Japan 2KG/2PG/2RG/2SG Diagnostic Solution

Hino 300 series 2*G(1.5t) Diagnostic Solution

Hino 300 series EV Diagnostic Solution

Hino Bus/Coach, Heavy Japan KL/VM/PJ Diagnostic Solution

Hino Bus/Coach, Heavy Japan BDG/BKG/PKG/PDG/BJG/ACG/ADG Diagnostic Solution

Hino Bus/Coach, Heavy Japan LDG/LKG/LJG/LNG/QPG/QRG/QQG/QSG/QTG Diagnostic Solution

Hino Bus/Coach, Heavy Japan 2DG/2KG/2RG/2SG/2TG Diagnostic Solution

Hino Bus/Coach, Heavy Articulated buses Diagnostic Solution

Hino Bus/Coach, Medium Japan KK/KL Diagnostic Solution

Hino Bus/Coach, Medium Japan PK/PB/PA Diagnostic Solution

Hino Bus/Coach, Medium Japan BDG/BKG/PDG/PKG Diagnostic Solution

Hino Bus/Coach, Medium Japan LDG/LKG/SKG/SDG/LNG Diagnostic Solution

Hino Bus/Coach, Medium Japan 2DG Diagnostic Solution

Hino Bus/Coach, Light Japan ADG/BDG/PDG/NBG Diagnostic Solution

Hino Bus/Coach, Light Japan KK Diagnostic Solution

Hino Bus/Coach, Light Japan PB/LD Diagnostic Solution

Hino Bus/Coach, Light Japan SDG/SKG Diagnostic Solution

Hino Bus/Coach, Light Japan 2DG Diagnostic Solution

Hino Retro Global Diagnostic Solution

Hino Industrial Engine EURO3 Diagnostic Solution

Hino Industrial Engine EURO4 Diagnostic Solution

Hino Industrial Engine TIER3/TIER4/GB4 Diagnostic Solution

Hino Industrial Engine Komatsu Light Armored Vehicle / High Mobility Vehicle Diagnostic Solution

Hino Other Other Diagnostic Solution

Hino 300 series(COE) (North America) North America (-10MY) Diagnostic Solution

Hino 300 series(COE) (North America) North America (12-13MY) Diagnostic Solution

Hino 300 series(COE) (North America) North America (14-15MY) Diagnostic Solution

Hino 300 series(COE) (North America) North America (16-18MY) Diagnostic Solution

Hino 300 series(COE) (North America) North America (19-20MY) Diagnostic Solution

Hino 300 series(COE) (North America) North America (21MY-) Diagnostic Solution

Hino 300 series (N engine) Global Diagnostic Solution

Hino 300 series (N engine) EURO5 With VCS Diagnostic Solution

Hino 300 series (N engine) EURO6 Diagnostic Solution

Hino 300 series (J engine) EURO5 With VCS Diagnostic Solution

Hino 300 series (J engine) Global Diagnostic Solution

Hino 300 series (J engine) EURO6 Diagnostic Solution

Hino BUS Global With VCS Diagnostic Solution

Hino BUS Global Without VCS Diagnostic Solution

Hino BUS Liesse2 Diagnostic Solution

Hino BUS EV Diagnostic Solution

Hino FC bus FC system DLC(A) Diagnostic Solution

Hino FC bus FC system DLC(B) Diagnostic Solution

Hino FC bus Chassis and body system Diagnostic Solution

Hino Bus/Coach, Light(Liesse2) Japan S*G(18MY) Diagnostic Solution

Hino Bus/Coach, Light(Liesse2) Japan 2*G(19-21MY) Diagnostic Solution

Hino Bus/Coach, Light(Liesse2) ###276(TBD) Diagnostic Solution

Hino Bus/Coach, Light(Liesse2) ###277(TBD) Diagnostic Solution

Hino Bus/Coach, Light(Liesse2) Japan 2*G(24MY) Diagnostic Solution

Hino 200 series (GD engine) EURO4/EURO5/EURO6 Diagnostic Solution

GENERAL INTRODUCTIONS:

GENERAL INTRODUCTION

GENERAL PRECAUTIONS

EN00Z00010100001

Some recommended and standard maintenance services for your vehicle are included in this section.

When performing maintenance on your vehicle be careful not to get injured by improper work.

Improper or incomplete work can cause a malfunction of the vehicle which may result in personal

injury and/or property damage. If you have any question about performing maintenance, please

consult your Hino dealer.

WARNING

When working on your vehicle, observe the following general precautions to prevent

death, personal injury and/or property damage in addition to the particular DANGERS,

WARNINGS, CAUTIONS and NOTICES in each chapter.

• Always wear safety glasses or goggles to protect your eyes.

• Remove rings, watches, ties, loose hanging jewelry and loose clothing before starting

work on the vehicle.

• Bind long hair securely behind the head.

• When working on the vehicle, apply the parking brake firmly, place the gear shift lever

in "Neutral" or "N" and block the wheels.

• Always turn off the starter switch to stop the engine, unless the operation requires the

engine running. Removing the key from the switch is recommended.

• To avoid serious burns, keep yourself away from hot metal parts such as the engine,

exhaust manifold, radiator, muffler, exhaust pipe and tail pipe.

• Do not smoke while working on the vehicle since fuel, and gas from battery are

flammable.

• Take utmost care when working on the battery. It contains corrosive sulfuric acid.

• Large electric current flows through the battery cable and starter cable. Be careful not

to cause a short which can result in personal injury and/or property damage.

• Read carefully and observe the instructions specified on the jack before using it.

• Use safety stands to support the vehicle whenever you need to work under it. It is

dangerous to work under a vehicle supported only by a jack.

• If it is necessary to run the engine after the hood is raised (tilted), make sure that the

parking brake is firmly applied, the wheels are blocked, and the gear shift lever is

positioned in "Neutral" before staring the engine.

• Run the engine only in a well-ventilated area to avoid inhalation of carbon monoxide.

• Keep yourself, your clothing and your tools away from moving parts such as the cooling

fan and V-belts when the engine is running.

• Be careful not to damage lines and hoses by stepping or holding your feet on them.

• Be careful not to leave any tool in the engine compartment. The tool may be hit by

moving parts, which can cause personal injury.

DEFINITION OF SAFETY TERMS

!DANGER

Indicates an extremely hazardous situation if proper procedures are not followed and could result

in death or serious injury.

!WARNING

Indicates a potential hazardous situation if proper procedures are not followed and could result in

death or serious injury.

!CAUTION

Indicates a hazardous situation if proper procedures are not followed and could result in serious

injury or damage to parts/equipment.

NOTICE

Indicates the need to follow proper procedures and to pay attention to precautions so that efficient

service is provided.

HINT

Provides additional information to help you to perform the repair efficiently.

PRECAUTIONS

EN00Z0001C100001

PRECAUTIONS FOR ELECTRICAL SYSTEM

1. REMOVING THE BATTERY CABLE

SAPH00Z000100016

! WARNING

• Be sure to wait for at least ten minutes after the starter key is turned to "LOCK" position

before you disconnect the battery terminals from the battery, as the vehicle data is

recorded on ECU and DCU starts working for the exhaust gas after treatment after the

starter key is turned to "LOCK" position.

Otherwise, the vehicle data will not be recorded on ECU properly and DCU will not

complete working properly, which may result in the malfunction of DPR system and

DEF-SCR system.

• The MIL (malfunction indicator light) may come on when the starter key is turned to "ON"

position again, even if you wait for at least ten minutes before disconnecting the battery

terminals from the battery after the starter key is turned to "LOCK" position. In this case,

use Hino-DX to clear the DTC (P204F and P068A), to turn off the MIL and to conduct DPR

regeneration manually.

(1) Before electrical system work, remove the cable from the minus terminal of the battery in order

to avoid burning caused by short-circuiting.

(2) To remove the battery cable, fully release the nut to avoid damage to the battery terminal. Never

twist the terminal.

2. HANDLING OF ELECTRONIC PARTS

SAPH00Z000100017

(1) Never give an impact to electronic parts of a computer or relay.

(2) Keep electronic parts away from high temperatures and humidity.

(3) Never splash water onto electronic parts in washing the vehicle.

(4) Do not remove the harness connector, electric component box, and cover except for repair and

inspection.If removal is necessary, pay attention that water and foreign matters do not attach or

enter to the connector, terminals, electric component box, and cover.

In restoration, make sure there is no attachment or entry of water and foreign matters and mount

them properly, because it causes degradation of waterproof function.

3. HANDLING OF WIRE HARNESS

SAPH00Z000100018

(1) Perform marking on a clamp and a clip and secure then in original position so that the wire

harness will not interfere with the end and acute angle section of the body and a bolt.

(2) To attach a part, take care not to bite the wire arness.

4. HANDLING OF CONNECTOR

SAPH00Z000100019

(1) To remove a connector, hold the connector (indicated by an arrow in the figure) to pull it out.

Never pull the harness.

(2) To remove a connector with lock, release the lock then pull it out.

(3) To connect a connector with lock, insert it until it clicks.

(4) To insert a test lead into the connector, insert it from behind the connector.

(5) In case it is difficult to insert a test lead from behind the connector, prepare a harness for

inspection and perform inspection.

5. INSTALLATION OF BATTERY DISCONNECT SWITCH

! WARNING

• Installation of the battery disconnect switch on the power supply circuit for the dosing

control unit of DEF-SCR (DCU) may damage or result in the malfunction of DEF-SCR

system.

• Be sure to read and follow the procedures and instructions on the service bulletin before

the installation of the battery disconnect switch.

6. HANDLING OF BATTERY DISCONNECT SWITCH

! WARNING

• Wait for at least one minute before using the battery Disconnect switch after the starter

key is turned to "LOCK" position.

Otherwise, the vehicle data will not be recorded on ECU properly, which may result in

the malfunction of DPR system.

PRECAUTIONS FOR ELECTRIC WELDING

1. PRECAUTION FOR ELECTRIC WELDING

Electrical components such as the alternator and tachograph are directly connected to the

battery and one end is earthed to the chassis frame. Under these conditions, welding

current will flow back along the earth circuit if electric welding is carried out and damage

may be caused to the alternator, tachograph, electrical components, etc.

Consequently, the following precautions are always to be taken during welding.

(1) Disconnect the earth terminal of the battery at the frame fitment and earth the welding equipment

securely to the frame itself. (Do not fit the welding equipment earth to such things as the tire rims,

brake pipes or fuel pipes and leaf spring, etc.)

a. Turn the starter switch off.

b. Disconnect the negative terminal of the battery.

c. Earth welding equipment securely, near to the area to be welded.

d. Put back battery negative ground as original condition.

e. Finally check the functioning of all instruments.

SAPH00Z000100020

(2) In order to prevent damage to ancillary equipment components from sparks during welding, take

steps such as putting fire-resistant covers over things like the engine, meters, steering wheel,

hoses, tubes, leaf spring and tires.