Hitachi ZH200-A Technical Manual

Size: 53.28 MB

Language: English

Machine: Hybrid Excavator

Machine Model: ZH200-A

Document: Technical Manual, Troubleshooting, Operational Principle, Electrical and Hydraulic Circuit Diagram

List Files:

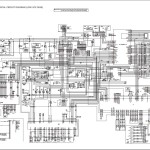

ZH200-A Electrical and Hydraulic Circuit Diagram TTDCF-EN-00(20121115) PDF (Pages: 11)

ZH200-A Technical Manual Operational Principle TODCF-EN-00(20130730) PDF (Pages: 545)

ZH200-A Technical Manual Operational Principle TODCF-EN-00(20140714) PDF (Pages: 545)

ZH200-A Technical Manual Troubleshooting TTDCF-EN-00(20130214) PDF (Pages: 612)

ZH200-A Technical Manual Troubleshooting TTDCF-EN-00(20140806) PDF (Pages: 612)

The Bookmarks of Hitachi ZH200-A Technical Manual:

ZH200-A Electrical and Hydraulic Circuit Diagram TTDCF-EN-00(20121115) PDF

ZH210-A/210LC-A ELECTRICAL CIRCUIT DIAGRAM (LOW VOLTAGE)

ZH210-A/210LC-A CONNECTORS

ZH210-A, ZH210LC-A ELECTRICAL CIRCUIT DIAGRAM (HIGH VOLTAGE)

ZH210-A/210LC-A CAB HARNESS

ZH210-A/210LC-A ENGINE HARNESS

ZH210-A/210LC-A GSM (MOBILE COMMUNICATION TERMINAL) HARNESS

ZH210-A/210LC-A MONITOR HARNESS

ZH210-A/210LC-A KEY SWITCH HARNESS PLAQUE

ZH210-A/ZH210LC-A PILOT SHUT-OFF SOLENOID VALVE HARNESS

ZH210-A/210LC-A REARVIEW CAMERA HARNESS

ZH210-A/210LC-A HYDRAULIC CIRCUIT DIAGRAM

ZH200-A Technical Manual Operational Principle TODCF-EN-00(20130730) PDF

TODCF-EN-00

INTRODUCTION

SYMBOL AND ABBREVIATION

SECTION AND GROUP CONTENTS

SECTION 1 GENERAL

Group 1 Specifications

Specifications Working Ranges (Grouser shoe)

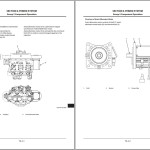

Group 2 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray)

Electrical System (Switch Panel)

Electrical System (Around Air Cleaner)

Electrical System (Relay, Sensor)

Electrical System (Battery)

Engine

Pump Device Around Pump Device

Control Valve

Signal Control Valve

Swing Device

Travel Device

5-Spool Solenoid Valve Unit

Layout of Attachment Spec. Parts(Hydraulic System)

Layout of Attachment Spec. Parts(Electrical System)

Group 3 Component Specifications

Engine

Engine Accessories

Hydraulic Component

Electrical Component

SECTION 2 SYSTEM Group 1 Controller

Outline

CAN Circuit

Group 2 Control System

Outline

Engine Control

Pump Control

Valve Control (Standard)

Valve Control (Option)

Other Control

Group 3 ECM System

Outline

Fuel Injection Control

Fuel Injection Amount Correction Control

EGR (Exhaust Gas Recirculation) Control

Preheating Control

Alarm Control

Engine Stop Control Group 4 Hydraulic System

Outline

Pilot Circuit

Main Circuit

Breaker / Pulverizer / Crusher Circuit (Optional)

Group 5 Electrical System

Outline

Main Circuit

Electric Power Circuit (Key Switch: OFF) CAN Circuit

Accessory Circuit

Starting Circuit (Key Switch: START) Charging Circuit (Key Switch: ON)

Surge Voltage Prevention Circuit

Pilot Shut-Off Circuit (Key Switch: ON) Auto Shut-Down Circuit

Engine Stop Circuit

Monitor Circuit

Security Circuit

Radio Circuit

Air Conditioner Circuit

Accessory Circuit

Work Light Circuit

Wiper / Washer Circuit Cab Light Circuit

SECTION 3 COMPONENT OPERATION

Group 1 Pump Device

Outline

Main Pump

Regulator Solenoid Valve

Pilot Pump

Pump Delivery Pressure Sensor

Pump Control Pressure Sensor

Group 2 Swing Device

Swing Device

Group 3 Control Valve

Outline

Hydraulic Circuit

Flow Combiner Valve

Main Relief Valve

Overload Relief Valve (with Make-Up Function) Regenerative Valve

Anti-Drift Valve

Flow Rate Control Valve

Digging Regenerative Valve

Boom Lower Meter-In Cut Valve

Auxiliary Flow Combiner Valve and BypassShut-Out Valve

Group 4 Pilot Valve

Outline

Operation (Front Attachment / Swing and TravelPilot Valves) Operation (Auxiliary / Positioning Pilot Valve) Shockless Function (Only for Travel Pilot Valve)

Group 5 Travel Device

Outline Travel Reduction Gear

Travel Motor

Parking Brake

Travel Brake Valve

Overload Relief Valve

Travel Mode Control

Group 6 Signal Control Valve

Outline

Pilot Port

Shuttle Valve

Shockless Valve

Pump 1 Flow Rate Control Valve,Pump 2 Flow Rate Control Valve,and Pump 3 Flow Rate Control Valve

Flow Combiner Valve Control Spool,Swing Parking Brake Release Spool

Group 7 Others (Upperstructure)

Pilot Shut-Off Solenoid Valve

Solenoid Valve

Hose Rupture Valve

Pilot Relief Valve

Recirculation Valve (Option)

Group 8 Others (Undercarriage)

Swing Bearing Center Joint

Track Adjuster (Front Idler Integrated Type)

SECTION 6 HYBRID SYSTEM

Group 1 General

Outline

Hybrid System

Electric Component

Group 2 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray) Assist Alternator Motor

Swing Device

Swing Control Solenoid Valve Unit

Swing Pilot Pressure Control Solenoid Valve Unit

Group 3 Component Specifications

Parts Related with Hybrid

Cooling System for Hybrid System

Group 4 Control of Hybrid System

Outline

Start-Up Control

Hydraulic-Electric Complex Swing Control

Hydraulic Independent Swing Control

Energy Management Control

Stop Control

Fault Processing Control

Swing Parking Brake

Cooling System for Hybrid System

Electric Power Circuit (Key Switch: OFF) Starting Circuit (Key Switch: START)

Group 5 Component Operation

Assist Alternator Motor

Swing Device

Swing Reduction Gear

Swing Hydraulic Motor

Swing Parking Brake

Valve Unit

Swing Low-Pressure Relief Valve Unit

Swing Electric Motor

Swing Pilot Pressure Control Solenoid ValveUnit

Swing Control Solenoid Valve Unit

HCU

PCU

Capacitor Unit

SERVICE MANUAL REVISION REQUEST FORM

ZH200-A Technical Manual Operational Principle TODCF-EN-00(20140714) PDF

TODCF-EN-00

INTRODUCTION

SYMBOL AND ABBREVIATION

SECTION AND GROUP CONTENTS

SECTION 1 GENERAL

Group 1 Specifications

Specifications Working Ranges (Grouser shoe)

Group 2 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray)

Electrical System (Switch Panel)

Electrical System (Around Air Cleaner)

Electrical System (Relay, Sensor)

Electrical System (Battery)

Engine

Pump Device Around Pump Device

Control Valve

Signal Control Valve

Swing Device

Travel Device

5-Spool Solenoid Valve Unit

Layout of Attachment Spec. Parts(Hydraulic System)

Layout of Attachment Spec. Parts(Electrical System)

Group 3 Component Specifications

Engine

Engine Accessories

Hydraulic Component

Electrical Component

SECTION 2 SYSTEM Group 1 Controller

Outline

CAN Circuit

Group 2 Control System

Outline

Engine Control

Pump Control

Valve Control (Standard)

Valve Control (Option)

Other Control

Group 3 ECM System

Outline

Fuel Injection Control

Fuel Injection Amount Correction Control

EGR (Exhaust Gas Recirculation) Control

Preheating Control

Alarm Control

Engine Stop Control Group 4 Hydraulic System

Outline

Pilot Circuit

Main Circuit

Breaker / Pulverizer / Crusher Circuit (Optional)

Group 5 Electrical System

Outline

Main Circuit

Electric Power Circuit (Key Switch: OFF) CAN Circuit

Accessory Circuit

Starting Circuit (Key Switch: START) Charging Circuit (Key Switch: ON)

Surge Voltage Prevention Circuit

Pilot Shut-Off Circuit (Key Switch: ON) Auto Shut-Down Circuit

Engine Stop Circuit

Monitor Circuit

Security Circuit

Radio Circuit

Air Conditioner Circuit

Accessory Circuit

Work Light Circuit

Wiper / Washer Circuit Cab Light Circuit

SECTION 3 COMPONENT OPERATION

Group 1 Pump Device

Outline

Main Pump

Regulator Solenoid Valve

Pilot Pump

Pump Delivery Pressure Sensor

Pump Control Pressure Sensor

Group 2 Swing Device

Swing Device

Group 3 Control Valve

Outline

Hydraulic Circuit

Flow Combiner Valve

Main Relief Valve

Overload Relief Valve (with Make-Up Function) Regenerative Valve

Anti-Drift Valve

Flow Rate Control Valve

Digging Regenerative Valve

Boom Lower Meter-In Cut Valve

Auxiliary Flow Combiner Valve and BypassShut-Out Valve

Group 4 Pilot Valve

Outline

Operation (Front Attachment / Swing and TravelPilot Valves) Operation (Auxiliary / Positioning Pilot Valve) Shockless Function (Only for Travel Pilot Valve)

Group 5 Travel Device

Outline Travel Reduction Gear

Travel Motor

Parking Brake

Travel Brake Valve

Overload Relief Valve

Travel Mode Control

Group 6 Signal Control Valve

Outline

Pilot Port

Shuttle Valve

Shockless Valve

Pump 1 Flow Rate Control Valve,Pump 2 Flow Rate Control Valve,and Pump 3 Flow Rate Control Valve

Flow Combiner Valve Control Spool,Swing Parking Brake Release Spool

Group 7 Others (Upperstructure)

Pilot Shut-Off Solenoid Valve

Solenoid Valve

Hose Rupture Valve

Pilot Relief Valve

Recirculation Valve (Option)

Group 8 Others (Undercarriage)

Swing Bearing Center Joint

Track Adjuster (Front Idler Integrated Type)

SECTION 6 HYBRID SYSTEM

Group 1 General

Outline

Hybrid System

Electric Component

Group 2 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray) Assist Alternator Motor

Swing Device

Swing Control Solenoid Valve Unit

Swing Pilot Pressure Control Solenoid Valve Unit

Group 3 Component Specifications

Parts Related with Hybrid

Cooling System for Hybrid System

Group 4 Control of Hybrid System

Outline

Start-Up Control

Hydraulic-Electric Complex Swing Control

Hydraulic Independent Swing Control

Energy Management Control

Stop Control

Fault Processing Control

Swing Parking Brake

Cooling System for Hybrid System

Electric Power Circuit (Key Switch: OFF) Starting Circuit (Key Switch: START)

Group 5 Component Operation

Assist Alternator Motor

Swing Device

Swing Reduction Gear

Swing Hydraulic Motor

Swing Parking Brake

Valve Unit

Swing Low-Pressure Relief Valve Unit

Swing Electric Motor

Swing Pilot Pressure Control Solenoid ValveUnit

Swing Control Solenoid Valve Unit

HCU

PCU

Capacitor Unit

SERVICE MANUAL REVISION REQUEST FORM

ZH200-A Technical Manual Troubleshooting TTDCF-EN-00(20130214) PDF

TTDCF-EN-00

INTRODUCTION

SYMBOL AND ABBREVIATION

SAFETY

SECTION AND GROUP CONTENTS

SECTION 4 OPERATIONAL PERFORMANCE TEST

Group 1 Introduction

Operational Performance Tests

Preparation for Performance Tests

Group 2 Standard

Operational Performance Standard Table

Main Pump P-Q Diagram (P1, P2)

Main Pump P-Q Diagram (P3)

Sensor Activating Range

MPDr. Monitor Indicating Values

Group 3 Engine Test

Engine Speed

Lubricant Consumption

Group 4 Machine Performance Test

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Parking Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Combined Operation of Boom Raise / Swing Function Check

Combined Operation of Boom Raise / Arm Roll-In Function Check

Group 5 Component Test

Primary Pilot Pressure

Secondary Pilot Pressure

5-Spool Solenoid Valve Set Pressure

2-Spool Solenoid Valve (for Swing Pilot Pressure Control) Set Pressure

Main Pump Delivery Pressure

Main Relief Set Pressure

Relief pressure (when relieving swing)

Overload Relief Valve Set Pressure

Main Pump Flow Rate Measurement

Swing Motor Drainage

Travel Motor Drainage

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Introduction Diagnosis Procedure

Electric System Inspection Precautions for Inspection and Maintenance

Instructions for Disconnecting Connectors

Fuse Inspection

Fusible Link Inspection

Battery Voltage Check

Alternator Check

Continuity Check

Voltage and Current Measurement

Check by False Signal

Test Harness

Group 2 Monitor

Outline

Operating Procedures of Service Menu

Setting Menu

Inspection of Engine Oil Level, Hour Meter and Fuel Gauge

Fuel Gauge and Coolant Temperature Gauge

Group 3 e-Service

Outline

List of Operation Data

Snapshot Data Communication System Group 4 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray)

Electrical System (Switch Panel)

Electrical System (Around Air Cleaner)

Electrical System (Relay, Sensor)

Electrical System (Battery)

Engine

Pump Device

Around Pump Device

Control Valve

Signal Control Valve

Swing Device

Travel Device

5-Spool Solenoid Valve Unit

Layout of Attachment Spec. Parts (Hydraulic System)

Layout of Attachment Spec. Parts (Electrical System)

Pilot Port

Group 5 Troubleshooting A

Troubleshooting A (Base Machine DiagnosisBy Using Fault Codes) Procedure

MC Fault Code List

ECM Fault Code List

Monitor Controller (Monitor) Fault Code List

Monitor Controller (Information) Fault Code List

Air Conditioner Controller Fault Code List

Communication Terminal Fault Code List

MC Fault Codes 11000 to 11002

MC Fault Code 11003

MC Fault Codes 11006, 11007,11009

Monitor Controller (Monitor) Fault Codes 13002, 13003, 13005

CAN0 Harness Check

MC Fault Codes 11008, 11010

Monitor Controller (Monitor) Fault Codes 13004, 13006, 13007

CAN1 Harness Check

MC Fault Code 11100

MC Fault Code 11101

MC Fault Codes 11200, 11202, 11203

MC Fault Codes 11206 to 11208

MC Fault Codes 11301 to 11303

MC Fault Codes 11304, 11307, 11325

MC Fault Code 11400

MC Fault Code 11401

MC Fault Code 11402

MC Fault Code 11403

MC Fault Code 11406

MC Fault Code 11407

MC Fault Code 11427

MC Fault Code 11428

MC Fault Code 11901

Monitor Controller (Information) Fault Codes 13304, 13310

Monitor Controller (Information) Fault Code 13311

Air Conditioner Controller Fault Codes 11 to 22

Air Conditioner Controller Fault Codes 43 to 92

Monitor Controller (Information) Fault Codes 20100 to 20146

Group 6 Troubleshooting B

Troubleshooting B (Machine Diagnosis by Using Troubleshooting Symptom) Procedure

Relationship between Machine Trouble Symptoms and Related Parts

Correlation between Trouble Symptoms and Part Failures

Engine System Troubleshooting

All Actuator System Troubleshooting

Front Attachment System Troubleshooting

Travel System Troubleshooting

Other System Troubleshooting

Exchange Inspection

How to Lower Boom in Case of Emergency and When Engine Stops without Hose Rupture Valve

How to Lower Boom in Case of Emergency and When Engine Stops with Hose Rupture Valve

Attachment Circuit Pressure Release Procedure

Group 7 Air Conditioner

Outline

Functions of Main Parts

Troubleshooting

Air Conditioner Controller Fault Code List

Air Conditioner Controller Fault Codes 11 to 22

Air Conditioner Controller Fault Codes 43 to 92

Work after Replacing Components

Refill Compressor Oil

Charge Air Conditioner with Refrigerant

Hose and Pipe Tightening Torque

SECTION 7 HYBRID TROUBLESHOOTING

Group 1 Standard

Operational Performance Standard Table

MPDr. Monitor Indicating Values

Relief Set Pressure (Relief Operation of Swing)

Swing Electric Motor Efficiency, Assist Alternator Motor Efficiency, Chopper Efficiency

Group 2 Diagnosing Procedure of Troubleshooting

Introduction

Fuse Inspection

Voltage and Current Measurement

Hybrid Component Inspection

Precautions for Inspection and Maintenance

Detect Voltage

Appearance Check

Check for Ground

Instructions for Disconnecting Connectors

How to use inspection equipments

Group 3 Monitor

Outline Service Menu

Group 4 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray)

Assist Alternator Motor Swing Device

Swing Control Solenoid Valve Unit

Swing Pilot Pressure Control Solenoid Valve Unit

Group 5 Troubleshooting A

Troubleshooting A (Base Machine Diagnosis By Using Fault Codes) Procedure

HCU Fault Code List HCU Fault Codes 19500 to 19503

HCU Fault Code 19503-3

HCU Fault Codes 19504, 19505

HCU Fault Codes 19506, 19507

HCU Fault Code 19508

HCU Fault Code 19509

HCU Fault Code 19511

HCU Fault Code 19512

HCU Fault Codes 19513 to 19515

Harness Check between HCU and PCU

HCU Fault Codes 19518 to 19522

CAN1 Harness Check

INV-CAN Harness Check

HCU Fault Code 19524

HCU Fault Code 19525

Harness Check between HCU and Water Cooling Pump

HCU Fault Codes 19532 to 19534

Harness Check between HCU and PCU

HCU Fault Code 19535

HCU Fault Code 19536

PCU Fault Code List

PCU Fault Code 19607

PCU Fault Codes 19611, 19612, and 19613

Harness Check between PCU and Capacitor Unit

PCU Fault Codes 19615, 19616

PCU Fault Code 19617

Power Harness Check between PCU and Swing Electric Motor

PCU Fault Code 19618

Power Harness Check between PCU and Capacitor Unit

PCU Fault Codes 19621, 19622

PCU Fault Codes 19623, 19624

Harness Check between PCU and Swing Electric Motor (Resolver)

PCU Fault Code 19627

Harness Check between PCU and Swing Electric Motor (Thermistor)

PCU Fault Code 19628

PCU Fault Code 19633

Harness Check between PCU and PUMP / H2 Connector

PCU Fault Code 19634

PCU Fault Code 19635

PCU Fault Codes 19637, 19638

PCU Fault Code 19641

PCU Fault Code 19642

PCU Fault Codes 19648, 19649

Group 6 Troubleshooting

Outline Relationship between Machine Trouble Symptoms and Related Parts

Correlation between Trouble Symptoms and Part Failures

Swing System Troubleshooting

Exchange Inspection

Applicability of Switch-Check Method

The Attached Diagram List

ZH200-A Technical Manual Troubleshooting TTDCF-EN-00(20140806) PDF

TTDCF-EN-00

INTRODUCTION

SYMBOL AND ABBREVIATION

SAFETY

SECTION AND GROUP CONTENTS

SECTION 4 OPERATIONAL PERFORMANCE TEST

Group 1 Introduction

Operational Performance Tests

Preparation for Performance Tests

Group 2 Standard

Operational Performance Standard Table

Main Pump P-Q Diagram (P1, P2)

Main Pump P-Q Diagram (P3)

Sensor Activating Range

MPDr. Monitor Indicating Values

Group 3 Engine Test

Engine Speed

Lubricant Consumption

Group 4 Machine Performance Test

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Parking Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Combined Operation of Boom Raise / Swing Function Check

Combined Operation of Boom Raise / Arm Roll-In Function Check

Group 5 Component Test

Primary Pilot Pressure

Secondary Pilot Pressure

5-Spool Solenoid Valve Set Pressure

2-Spool Solenoid Valve (for Swing Pilot Pressure Control) Set Pressure

Main Pump Delivery Pressure

Main Relief Set Pressure

Relief pressure (when relieving swing)

Overload Relief Valve Set Pressure

Main Pump Flow Rate Measurement

Swing Motor Drainage

Travel Motor Drainage

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Introduction Diagnosis Procedure

Electric System Inspection Precautions for Inspection and Maintenance

Instructions for Disconnecting Connectors

Fuse Inspection

Fusible Link Inspection

Battery Voltage Check

Alternator Check

Continuity Check

Voltage and Current Measurement

Check by False Signal

Test Harness

Group 2 Monitor

Outline

Operating Procedures of Service Menu

Setting Menu

Inspection of Engine Oil Level, Hour Meter and Fuel Gauge

Fuel Gauge and Coolant Temperature Gauge

Group 3 e-Service

Outline

List of Operation Data

Snapshot Data Communication System Group 4 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray)

Electrical System (Switch Panel)

Electrical System (Around Air Cleaner)

Electrical System (Relay, Sensor)

Electrical System (Battery)

Engine

Pump Device

Around Pump Device

Control Valve

Signal Control Valve

Swing Device

Travel Device

5-Spool Solenoid Valve Unit

Layout of Attachment Spec. Parts (Hydraulic System)

Layout of Attachment Spec. Parts (Electrical System)

Pilot Port

Group 5 Troubleshooting A

Troubleshooting A (Base Machine DiagnosisBy Using Fault Codes) Procedure

MC Fault Code List

ECM Fault Code List

Monitor Controller (Monitor) Fault Code List

Monitor Controller (Information) Fault Code List

Air Conditioner Controller Fault Code List

Communication Terminal Fault Code List

MC Fault Codes 11000 to 11002

MC Fault Code 11003

MC Fault Codes 11006, 11007,11009

Monitor Controller (Monitor) Fault Codes 13002, 13003, 13005

CAN0 Harness Check

MC Fault Codes 11008, 11010

Monitor Controller (Monitor) Fault Codes 13004, 13006, 13007

CAN1 Harness Check

MC Fault Code 11100

MC Fault Code 11101

MC Fault Codes 11200, 11202, 11203

MC Fault Codes 11206 to 11208

MC Fault Codes 11301 to 11303

MC Fault Codes 11304, 11307, 11325

MC Fault Code 11400

MC Fault Code 11401

MC Fault Code 11402

MC Fault Code 11403

MC Fault Code 11406

MC Fault Code 11407

MC Fault Code 11427

MC Fault Code 11428

MC Fault Code 11901

Monitor Controller (Information) Fault Codes 13304, 13310

Monitor Controller (Information) Fault Code 13311

Air Conditioner Controller Fault Codes 11 to 22

Air Conditioner Controller Fault Codes 43 to 92

Monitor Controller (Information) Fault Codes 20100 to 20146

Group 6 Troubleshooting B

Troubleshooting B (Machine Diagnosis by Using Troubleshooting Symptom) Procedure

Relationship between Machine Trouble Symptoms and Related Parts

Correlation between Trouble Symptoms and Part Failures

Engine System Troubleshooting

All Actuator System Troubleshooting

Front Attachment System Troubleshooting

Travel System Troubleshooting

Other System Troubleshooting

Exchange Inspection

How to Lower Boom in Case of Emergency and When Engine Stops without Hose Rupture Valve

How to Lower Boom in Case of Emergency and When Engine Stops with Hose Rupture Valve

Attachment Circuit Pressure Release Procedure

Group 7 Air Conditioner

Outline

Functions of Main Parts

Troubleshooting

Air Conditioner Controller Fault Code List

Air Conditioner Controller Fault Codes 11 to 22

Air Conditioner Controller Fault Codes 43 to 92

Work after Replacing Components

Refill Compressor Oil

Charge Air Conditioner with Refrigerant

Hose and Pipe Tightening Torque

SECTION 7 HYBRID TROUBLESHOOTING

Group 1 Standard

Operational Performance Standard Table

MPDr. Monitor Indicating Values

Relief Set Pressure (Relief Operation of Swing)

Swing Electric Motor Efficiency, Assist Alternator Motor Efficiency, Chopper Efficiency

Group 2 Diagnosing Procedure of Troubleshooting

Introduction

Fuse Inspection

Voltage and Current Measurement

Hybrid Component Inspection

Precautions for Inspection and Maintenance

Detect Voltage

Appearance Check

Check for Ground

Instructions for Disconnecting Connectors

How to use inspection equipments

Group 3 Monitor

Outline Service Menu

Group 4 Component Layout

Main Component

Electrical System (Overview)

Electrical System (Rear Tray)

Assist Alternator Motor Swing Device

Swing Control Solenoid Valve Unit

Swing Pilot Pressure Control Solenoid Valve Unit

Group 5 Troubleshooting A

Troubleshooting A (Base Machine Diagnosis By Using Fault Codes) Procedure

HCU Fault Code List HCU Fault Codes 19500 to 19503

HCU Fault Code 19503-3

HCU Fault Codes 19504, 19505

HCU Fault Codes 19506, 19507

HCU Fault Code 19508

HCU Fault Code 19509

HCU Fault Code 19511

HCU Fault Code 19512

HCU Fault Codes 19513 to 19515

Harness Check between HCU and PCU

HCU Fault Codes 19518 to 19522

CAN1 Harness Check

INV-CAN Harness Check

HCU Fault Code 19524

HCU Fault Code 19525

Harness Check between HCU and Water Cooling Pump

HCU Fault Codes 19532 to 19534

Harness Check between HCU and PCU

HCU Fault Code 19535

HCU Fault Code 19536

PCU Fault Code List

PCU Fault Code 19607

PCU Fault Codes 19611, 19612, and 19613

Harness Check between PCU and Capacitor Unit

PCU Fault Codes 19615, 19616

PCU Fault Code 19617

Power Harness Check between PCU and Swing Electric Motor

PCU Fault Code 19618

Power Harness Check between PCU and Capacitor Unit

PCU Fault Codes 19621, 19622

PCU Fault Codes 19623, 19624

Harness Check between PCU and Swing Electric Motor (Resolver)

PCU Fault Code 19627

Harness Check between PCU and Swing Electric Motor (Thermistor)

PCU Fault Code 19628

PCU Fault Code 19633

Harness Check between PCU and PUMP / H2 Connector

PCU Fault Code 19634

PCU Fault Code 19635

PCU Fault Codes 19637, 19638

PCU Fault Code 19641

PCU Fault Code 19642

PCU Fault Codes 19648, 19649

Group 6 Troubleshooting

Outline Relationship between Machine Trouble Symptoms and Related Parts

Correlation between Trouble Symptoms and Part Failures

Swing System Troubleshooting

Exchange Inspection

Applicability of Switch-Check Method

The Attached Diagram List