Komatsu HD1500-8 Shop Manual SEN06990-00

Data Size: 122.79 MB

File Type: PDF

Language: English

Manufacturer: Komatsu

Applicable Machine: Dump Truck

Document: Shop Manual, Error Code, Electrical Schematic, Hydraulic Schematic

Machine Model: Komatsu HD1500-8 Dump Truck

Serial Number: 81228 and up

Book Number: SEN06990-00

Page: 3068 Pages

List Contents:

00 Index and Foreword

Foreword, Safety, Basic Information

How to Read the Shop Manual

Safety Notice for Operation

Precautions to Prevent Fire

Procedures If Fire Occurs

Precautions When You Dispose of Waste Materials

Engine Technology to Conform Exhaust Gas Emission

Precautions When You Handle Hydraulic Equipment

Precautions When You Disconnect and Connect Pipings

Precautions When You Handle Electrical Equipment

Precautions When You Handle Fuel System Equipment

Precautions When You Handle Intake System Equipment

Practical Use of KOMTRAX

Disconnect and Connect Push-Pull Type Coupler

Precautions for Disconnection and Connection of Connectors

How to Disconnect and Connect Deutsch Connector

How to Disconnect and Connect Slide Lock Type Connector

How to Disconnect and Connect Connector with Lock to Pull

How to Disconnect and Connect Connector with Lock to Push

How to Disconnect and Connect Connector with Housing to Rotate

HOW TO READ ELECTRICAL WIRE CODE

Explanation of Terms for Maintenance Standard

Standard Tightening Torque Table

Conversion Table

Abbreviation List

01 Specifications

Table of Contents

Specifications

Specification Drawing

Specifications

Weight Table

FUEL, COOLANT, AND LUBRICATING OIL

10 Structure and Function

Table of Contents

Boot-up System

LAYOUT DRAWING OF BOOT-UP SYSTEM

System Operating Lamp System

Battery Disconnect Switch

STARTING MOTOR DISCONNECT SWITCH

Engine Shutdown Secondary Switch

EXTERNAL POWER SUPPLY ENGINE PREHEATER

Engine System

LAYOUT DRAWING OF ENGINE SYSTEM

Engine Control System

Component Parts of Engine System

Cooling System

LAYOUT DRAWING OF COOLING SYSTEM

FAN SPEED CONTROL SYSTEM OF FAN CLUTCH

Component Parts of Cooling System

Control System

LAYOUT DRAWING OF CONTROL SYSTEM

LAYOUT DRAWING OF CONTROL SYSTEM (MACHINE WITH MOBILE COMMUNICATION TERMINAL)

RETARDER AND HOIST CONTROL SYSTEM

Machine Monitor System

Rearview Monitor System

KOMTRAX Plus System

Payload Meter System

Drowsiness Detection System

Component Parts of Control System

Hydraulic System

LAYOUT DRAWING OF HYDRAULIC SYSTEM

COMPONENT PARTS OF HYDRAULIC SYSTEM

Power Train System

LAYOUT DRAWING OF POWER TRAIN SYSTEM

Transmission Control System

Gear Shift Control System

Direction Control System

Komatsu Traction Control System (KTCS)

Travel Speed Limitation System

REAR AXLE OIL FILTRATION SYSTEM

COMPONENT PARTS OF POWER TRAIN SYSTEM

Work Equipment System

Work Equipment Control

Hoist Control

Component Parts of Work Equipment System

Steering System

LAYOUT DRAWING OF STEERING SYSTEM

FUNCTION OF STEERING SYSTEM

Steering Column

Steering Linkage

COMPONENT PARTS OF STEERING SYSTEM

Brake System

LAYOUT DRAWING OF BRAKE SYSTEM

Retarder Control

ARSC System

Component Parts of Brake System

Auto-Greasing System

LAYOUT DRAWING OF AUTO-GREASING SYSTEM

AUTO-GREASING SYSTEM DIAGRAM

FUNCTION OF AUTO-GREASING SYSTEM

GREASE REFILL AUTOMATIC STOP SYSTEM

Auto-Greasing System

SERVICE CENTER

LAYOUT DRAWING OF SERVICE CENTER

FUNCTION OF SERVICE CENTER

Undercarriage and Frame

REAR AXLE SUPPORT

Suspension

Front Suspension

Rear Suspension

Front Suspension Cylinder

Rear Suspension Cylinder

Work Equipment

STRUCTURE OF WORK EQUIPMENT

CAB Related Parts

ROPS CAB

CAB Mount

Lifting System

Power Ladder System

20 Standard Value Table

Table of Contents

Standard Value Table for Engine

STANDARD VALUE TABLE FOR ENGINE: HD1500-8

Standard Value Table for Machine

STANDARD VALUE TABLE FOR MACHINE: HD1500-8

MACHINE POSTURE AND PROCEDURE FOR MEASURING PERFORMANCE

30 Testing and Adjusting

Table of Contents

Precautions Before Work

Related Information on Testing and Adjusting

TOOLS TO TEST AND ADJUST

Engine and Cooling System

TEST ENGINE SPEED

TEST EXHAUST GAS COLOR

TEST BLOWBY PRESSURE

TEST FUEL PRESSURE

BLEED AIR FROM FUEL CIRCUIT

TEST TORQUE CONVERTER STALL SPEED

Power Train

TEST POWER TRAIN OIL PRESSURE

ADJUST TRANSMISSION INPUT SHAFT SPEED SENSOR

ADJUST TRANSMISSION INTERMEDIATE SHAFT SPEED SENSOR

ADJUST TRANSMISSION OUTPUT SHAFT SPEED SENSOR

CHECK AFTER ADJUSTING TRANSMISSION SPEED SENSOR

FLUSH TORQUE CONVERTER AND TRANSMISSION HYDRAULIC CIRCUIT

CLEAN FINAL DRIVE CASE MAGNET

MOVE MACHINE WITH ELECTRICAL SYSTEM PROBLEMS

STEERING SYSTEM

TEST STEERING CIRCUIT OIL PRESSURE

TEST STEERING CYLINDER PRESSURE

BLEED AIR FROM STEERING CYLINDER CIRCUIT

Brake System

RELEASE PRESSURE IN BRAKE ACCUMULATOR CIRCUIT

TEST WHEEL BRAKE OIL PRESSURE

TEST AND ADJUST BRAKE ACCUMULATOR PRESSURE

TEST AND PRESSURIZE BRAKE ACCUMULATOR WITH NITROGEN GAS

PROCEDURE TO RELEASE NITROGEN GAS WHEN DISPOSING ACCUMULATOR

TEST BRAKE PERFORMANCE

BLEED AIR FROM BRAKE CIRCUIT

TEST PARKING BRAKE OIL PRESSURE

RELEASE PARKING BRAKE MANUALLY

TEST THE AMOUNT OF WHEEL BRAKE DISC WEAR

Hydraulic System

TEST HOIST CIRCUIT OIL PRESSURE

TEST HOIST CYLINDER SUPPLY PRESSURE

TEST OIL PRESSURE OF HOIST EPC VALVE CIRCUIT

TEST AND ADJUST FRONT SUSPENSION CYLINDER

TEST AND ADJUST REAR SUSPENSION CYLINDER

BLEED AIR FROM HYDRAULIC CIRCUIT

CALIBRATION OF LADDER POSITION

Work Equipment

TEST AND ADJUST DUMP BODY POSITIONER SENSOR

LOWER THE DUMP BODY MANUALLY

LIFT THE DUMP BODY MANUALLY

LIFT THE DUMP BODY WITH BUDDY SYSTEM

CAB Related Parts

ADJUST STEERING WHEEL TILT LOCK LEVER

ADJUST RATTLING OPERATOR'S SEAT

ADJUST CLEARANCE OF ESCAPE DOOR

LIFTING SYSTEM

BLEED AIR FROM POWER LADDER CYLINDER

Electrical System

SET AND ADJUST EACH EQUIPMENT

SET AND OPERATE OF MACHINE MONITOR

START UP KOMTRAX TERMINAL

STOP USE OF KOMTRAX TERMINAL

STOP USE OF KOMTRAX TERMINAL (MACHINE WITH MOBILE COMMUNICATION TERMINAL)

SETTING DEFAULT OF KOMTRAX Plus CONTROLLER

SETTING DEFAULT OF WIRELESS LAN MODEM

DOWNLOAD KOMTRAX Plus CONTROLLER DATA

ADJUST WHEN KOMTRAX Plus CONTROLLER IS REPLACED

ADJUST WHEN WIRELESS LAN MODEM IS REPLACED

SETTING OF MOBILE COMMUNICATION TERMINAL

Set Driver Status Monitor

VOLTAGE CIRCUIT OF ENGINE CONTROLLER WORK

BATTERY DISCONNECT SWITCH WORK

BATTERY DISCONNECT SWITCH WORK (MACHINE WITH MOBILE COMMUNICATION TERMINAL)

TEST DIODES

Pm Clinic

Pm CLINIC SERVICE

PERFORM QUICK Pm

40 Troubleshooting

Table of Contents

Precautions Before Work

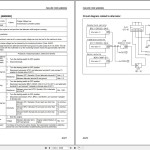

Related Information to Troubleshooting

General Troubleshooting Points

Sequence of Events in Troubleshooting

CHECKS BEFORE TROUBLESHOOTING

INSPECTION PROCEDURE BEFORE TROUBLESHOOTING

TESTING IN ACCORDANCE WITH TESTING PROCEDURE

ELECTRICAL SYSTEM TROUBLESHOOTING - PREPARATION

PROCEDURE FOR TESTING AND TROUBLESHOOTING

SYMPTOM AND TROUBLESHOOTING NUMBERS

INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE

CONNECTORS LIST AND LAYOUT

CONNECTOR CONTACT IDENTIFICATION

T-Branch Box and T-Branch Adapter Table

FUSE LOCATION TABLE

PREPARATION FOR TROUBLESHOOTING OF MACHINE MONITOR

Procedure to Make Harness Checker on Machine Monitor LCD Unit

FAILURE CODES TABLE

Troubleshooting by Failure Code (Display of Code)

FAILURE CODE [1500L0]

FAILURE CODE [15B0NX]

FAILURE CODE [15F0KM]

FAILURE CODE [15F0MB]

FAILURE CODE [15F7KM]

FAILURE CODE [15G0MW]

FAILURE CODE [15G7KM]

FAILURE CODE [15H0MW]

FAILURE CODE [15J0MW]

FAILURE CODE [15K0MW]

FAILURE CODE [15L0MW]

FAILURE CODE [15M0MW]

FAILURE CODE [15N0MW]

FAILURE CODE [15SBL1]

BLEED AIR FROM POWER LADDER CYLINDER

Electrical System

SET AND ADJUST EACH EQUIPMENT

SET AND OPERATE OF MACHINE MONITOR

START UP KOMTRAX TERMINAL

STOP USE OF KOMTRAX TERMINAL

STOP USE OF KOMTRAX TERMINAL (MACHINE WITH MOBILE COMMUNICATION TERMINAL)

SETTING DEFAULT OF KOMTRAX Plus CONTROLLER

SETTING DEFAULT OF WIRELESS LAN MODEM

DOWNLOAD KOMTRAX Plus CONTROLLER DATA

ADJUST WHEN KOMTRAX Plus CONTROLLER IS REPLACED

ADJUST WHEN WIRELESS LAN MODEM IS REPLACED

SETTING OF MOBILE COMMUNICATION TERMINAL

Set Driver Status Monitor

VOLTAGE CIRCUIT OF ENGINE CONTROLLER WORK

BATTERY DISCONNECT SWITCH WORK

BATTERY DISCONNECT SWITCH WORK (MACHINE WITH MOBILE COMMUNICATION TERMINAL)

TEST DIODES

Pm Clinic

Pm CLINIC SERVICE

PERFORM QUICK Pm

40 Troubleshooting

Table of Contents

Precautions Before Work

Related Information to Troubleshooting

General Troubleshooting Points

Sequence of Events in Troubleshooting

CHECKS BEFORE TROUBLESHOOTING

INSPECTION PROCEDURE BEFORE TROUBLESHOOTING

TESTING IN ACCORDANCE WITH TESTING PROCEDURE

ELECTRICAL SYSTEM TROUBLESHOOTING - PREPARATION

PROCEDURE FOR TESTING AND TROUBLESHOOTING

SYMPTOM AND TROUBLESHOOTING NUMBERS

INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE

CONNECTORS LIST AND LAYOUT

CONNECTOR CONTACT IDENTIFICATION

T-Branch Box and T-Branch Adapter Table

FUSE LOCATION TABLE

PREPARATION FOR TROUBLESHOOTING OF MACHINE MONITOR

Procedure to Make Harness Checker on Machine Monitor LCD Unit

FAILURE CODES TABLE

Troubleshooting by Failure Code (Display of Code)

FAILURE CODE [1500L0]

FAILURE CODE [15B0NX]

FAILURE CODE [15F0KM]

FAILURE CODE [15F0MB]

FAILURE CODE [15F7KM]

FAILURE CODE [15G0MW]

FAILURE CODE [15G7KM]

FAILURE CODE [15H0MW]

FAILURE CODE [15J0MW]

FAILURE CODE [15K0MW]

FAILURE CODE [15L0MW]

FAILURE CODE [15M0MW]

FAILURE CODE [15N0MW]

FAILURE CODE [15SBL1]

FAILURE CODE [D1EHKB]

FAILURE CODE [D1EHKY]

FAILURE CODE [D1ENKZ]

FAILURE CODE [D1EPKA]

FAILURE CODE [D1EPKB]

FAILURE CODE [D1EPKY]

FAILURE CODE [D1EQKA]

FAILURE CODE [D1EQKB]

FAILURE CODE [D1EQKY]

FAILURE CODE [D1ERKA]

FAILURE CODE [D1ERKB]

FAILURE CODE [D1ERKY]

FAILURE CODE [D1ESKA]

FAILURE CODE [D1ESKB]

FAILURE CODE [D1ESKY]

FAILURE CODE [D1EWKA]

FAILURE CODE [D1EWKB]

FAILURE CODE [D1EWKY]

FAILURE CODE [D1J0KB]

Failure Code [D5WNKZ]

FAILURE CODE [D5ZHL6]

FAILURE CODE [D862KA]

FAILURE CODE [DAF0KT]

FAILURE CODE [DAF0MB]

FAILURE CODE [DAF0MC]

FAILURE CODE [DAF3KK]

FAILURE CODE [DAF8KB]

FAILURE CODE [DAFDKB]

FAILURE CODE [DAFGMC]

FAILURE CODE [DAFLKA]

FAILURE CODE [DAFLKB]

FAILURE CODE [DAFQKR]

FAILURE CODE [DAQ0KK]

FAILURE CODE [DAQ0KT]

FAILURE CODE [DAQ0MC]

FAILURE CODE [DAQ1KA]

FAILURE CODE [DAQ2KK]

FAILURE CODE [DAQ9KQ]

FAILURE CODE [DAQLKA]

FAILURE CODE [DAQLKB]

FAILURE CODE [DAQQKR]

FAILURE CODE [DAQRKR]

FAILURE CODE [DAQRMA]

FAILURE CODE [DAQV00]

FAILURE CODE [DAQW00]

FAILURE CODE [DAZ9KQ]

FAILURE CODE [DAZQKR]

FAILURE CODE [DB10KT]

FAILURE CODE [DB10MC]

FAILURE CODE [DB11KA]

FAILURE CODE [DB12KK]

FAILURE CODE [DB13KK]

FAILURE CODE [DB19KQ]

FAILURE CODE [DB1LKA]

FAILURE CODE [DB1LKB]

FAILURE CODE [DB1QKR]

FAILURE CODE [DB1QMA]

FAILURE CODE [DB1RKR]

FAILURE CODE [DB1RKR] (For machines equipped with Drowsiness Detection system)

FAILURE CODE [DB2QKR]

FAILURE CODE [DB2QKR] (For machines equipped with Drowsiness Detection system)

FAILURE CODE [DBBUKM]

FAILURE CODE [DBBUKR]

FAILURE CODE [DBP0KM]

FAILURE CODE [DBP0KT]

FAILURE CODE [DBP0NR]

FAILURE CODE [DBP5KP]

FAILURE CODE [DBPLKA]

FAILURE CODE [DBPLKB]

FAILURE CODE [DBPQKR]

FAILURE CODE [DBPRKR]

FAILURE CODE [DBPRMA]

FAILURE CODE [DBPUKR]

FAILURE CODE [DBPVKR]

FAILURE CODE [DBPWKR]

FAILURE CODE [DBPXKR]

FAILURE CODE [DBV0MC]

FAILURE CODE [DBV1KK]

FAILURE CODE [DBV6KB]

FAILURE CODE [DBV7KB]

FAILURE CODE [DBVLKA]

FAILURE CODE [DBVLKB]

FAILURE CODE [DBVQKR]

FAILURE CODE [DBVRKR]

FAILURE CODE [DBVVKR]

FAILURE CODE [DBVWKR]

Failure Code [DCR0MC]

Failure Code [DCR2KK]

Failure Code [DCR8L4]

Failure Code [DCR9KQ]

Failure Code [DCRLKA]

Failure Code [DCRLKB]

Failure Code [DCRQKR]

Failure Code [DCRRKR]

FAILURE CODE [DDAAL6]

FAILURE CODE [DDD7KX]

FAILURE CODE [DDDGL4]

FAILURE CODE [DDDHL4]

FAILURE CODE [DDTHKA]

FAILURE CODE [DDTJKA]

FAILURE CODE [DDTKKA]

FAILURE CODE [DDTLKA]

FAILURE CODE [DDTMKA]

FAILURE CODE [DDTNKA]

FAILURE CODE [DDTPKA]

FAILURE CODE [DDU1KA]

FAILURE CODE [DF10KA]

FAILURE CODE [DF10KB]

FAILURE CODE [DGE5KX]

FAILURE CODE [DGF1KX]

FAILURE CODE [DGR2KB]

FAILURE CODE [DGR2L8]

FAILURE CODE [DGR4KB]

FAILURE CODE [DGR4L8]

FAILURE CODE [DGR6KB]

FAILURE CODE [DGR6L8]

FAILURE CODE [DGREKB]

FAILURE CODE [DGREL8]

FAILURE CODE [DGT1KX]

FAILURE CODE [DHP4KY]

FAILURE CODE [DHP4KZ]

FAILURE CODE [DHP5KY]

FAILURE CODE [DHP5KZ]

FAILURE CODE [DHP6KA]

FAILURE CODE [DHP6KX]

FAILURE CODE [DHP6KY]

FAILURE CODE [DHP6KZ]

FAILURE CODE [DHP7KA]

FAILURE CODE [DHP7KX]

FAILURE CODE [DHP7KY]

FAILURE CODE [DHP7KZ]

FAILURE CODE [DHQ2KX]

FAILURE CODE [DHQ4KX]

FAILURE CODE [DHQ6KX]

FAILURE CODE [DHT5KX]

FAILURE CODE [DHT5L6]

FAILURE CODE [DHT7KX]

FAILURE CODE [DHT7L6]

FAILURE CODE [DHT8KX]

FAILURE CODE [DHT8ZG]

FAILURE CODE [DHU2KX]

FAILURE CODE [DHU3KX]

FAILURE CODE [DHUBKX]

FAILURE CODE [DHUCKX]

FAILURE CODE [DHUDKX]

FAILURE CODE [DHUEKX]

FAILURE CODE [DHUHKX]

FAILURE CODE [DHUJKX]

FAILURE CODE [DHUKKX]

FAILURE CODE [DHULKX]

FAILURE CODE [DHUMKX]

FAILURE CODE [DHUQKX]

FAILURE CODE [DHUSKX]

FAILURE CODE [DJF1KA]

FAILURE CODE [DK30KX]

FAILURE CODE [DK51L5]

FAILURE CODE [DK52KX]

FAILURE CODE [DK53L8]

FAILURE CODE [DK54KX]

FAILURE CODE [DK5VKX]

FAILURE CODE [DK5VMA]

FAILURE CODE [DK60KX]

FAILURE CODE [DKH0KX]

FAILURE CODE [DKH1KX]

FAILURE CODE [DLF1KA]

FAILURE CODE [DLF1LC]

FAILURE CODE [DLF2KA]

FAILURE CODE [DLF2LC]

FAILURE CODE [DLF8LC]

FAILURE CODE [DLF9LC]

FAILURE CODE [DLFKLC]

FAILURE CODE [DLFLLC]

FAILURE CODE [DLT3KA]

FAILURE CODE [DLT3LC]

FAILURE CODE [DX13KY]

FAILURE CODE [DX30K4]

FAILURE CODE [DX30KA]

FAILURE CODE [DX30KB]

FAILURE CODE [DX30KY]

FAILURE CODE [DX30MA]

FAILURE CODE [DX33K4]

FAILURE CODE [DX33KA]

FAILURE CODE [DX33KB]

FAILURE CODE [DX33KY]

FAILURE CODE [DX33MA]

FAILURE CODE [DX37K4]

FAILURE CODE [DX37KA]

FAILURE CODE [DX37KB]

FAILURE CODE [DX37KY]

FAILURE CODE [DX37MA]

FAILURE CODE [DX38K4]

FAILURE CODE [DX38KA]

FAILURE CODE [DX38KB]

FAILURE CODE [DX38KY]

FAILURE CODE [DX38MA]

FAILURE CODE [DX42KZ]

FAILURE CODE [DX43KZ]

FAILURE CODE [DXH1KA]

FAILURE CODE [DXH1KB]

FAILURE CODE [DXH1KY]

FAILURE CODE [DXH2KA]

FAILURE CODE [DXH2KB]

FAILURE CODE [DXH2KY]

FAILURE CODE [DXH3KA]

FAILURE CODE [DXH3KB]

FAILURE CODE [DXH3KY]

FAILURE CODE [DXH4KA]

FAILURE CODE [DXH4KB]

FAILURE CODE [DXH4KY]

FAILURE CODE [DXH5KA]

FAILURE CODE [DXH5KB]

FAILURE CODE [DXH5KY]

FAILURE CODE [DXH6KA]

FAILURE CODE [DXH6KB]

FAILURE CODE [DXH6KY]

FAILURE CODE [DXH7KA]

FAILURE CODE [DXH7KB]

FAILURE CODE [DXH7KY]

FAILURE CODE [DXHHKA]

FAILURE CODE [DXHHKB]

FAILURE CODE [DXHHKY]

FAILURE CODE [DY30MA]

FAILURE CODE [DY30MC]

FAILURE CODE [DY30ME]

FAILURE CODE [DY32MC]

FAILURE CODE [F9A1KK]

FAILURE CODE [F9A2KK]

FAILURE CODE [F9ALKA]

FAILURE CODE [F9ALKB]

FAILURE CODE [F9AQKR]

FAILURE CODE [F9ARKR]

FAILURE CODE [F9AUKA]

FAILURE CODE [DX13KY]

FAILURE CODE [DX30K4]

FAILURE CODE [DX30KA]

FAILURE CODE [DX30KB]

FAILURE CODE [DX30KY]

FAILURE CODE [DX30MA]

FAILURE CODE [DX33K4]

FAILURE CODE [DX33KA]

FAILURE CODE [DX33KB]

FAILURE CODE [DX33KY]

FAILURE CODE [DX33MA]

FAILURE CODE [DX37K4]

FAILURE CODE [DX37KA]

FAILURE CODE [DX37KB]

FAILURE CODE [DX37KY]

FAILURE CODE [DX37MA]

FAILURE CODE [DX38K4]

FAILURE CODE [DX38KA]

FAILURE CODE [DX38KB]

FAILURE CODE [DX38KY]

FAILURE CODE [DX38MA]

FAILURE CODE [DX42KZ]

FAILURE CODE [DX43KZ]

FAILURE CODE [DXH1KA]

FAILURE CODE [DXH1KB]

FAILURE CODE [DXH1KY]

FAILURE CODE [DXH2KA]

FAILURE CODE [DXH2KB]

FAILURE CODE [DXH2KY]

FAILURE CODE [DXH3KA]

FAILURE CODE [DXH3KB]

FAILURE CODE [DXH3KY]

FAILURE CODE [DXH4KA]

FAILURE CODE [DXH4KB]

FAILURE CODE [DXH4KY]

FAILURE CODE [DXH5KA]

FAILURE CODE [DXH5KB]

FAILURE CODE [DXH5KY]

FAILURE CODE [DXH6KA]

FAILURE CODE [DXH6KB]

FAILURE CODE [DXH6KY]

FAILURE CODE [DXH7KA]

FAILURE CODE [DXH7KB]

FAILURE CODE [DXH7KY]

FAILURE CODE [DXHHKA]

FAILURE CODE [DXHHKB]

FAILURE CODE [DXHHKY]

FAILURE CODE [DY30MA]

FAILURE CODE [DY30MC]

FAILURE CODE [DY30ME]

FAILURE CODE [DY32MC]

FAILURE CODE [F9A1KK]

FAILURE CODE [F9A2KK]

FAILURE CODE [F9ALKA]

FAILURE CODE [F9ALKB]

FAILURE CODE [F9AQKR]

FAILURE CODE [F9ARKR]

FAILURE CODE [F9AUKA]

Troubleshooting of Electrical System (E-Mode)

E-1 ENGINE DOES NOT START (ENGINE DOES NOT CRANK)

E-2 ALL OF LCD UNIT, LED UNIT, AND METER UNIT ON MACHINE MONITOR DISPLAY NOTHING

E-3 LCD UNIT ON MACHINE MONITOR DISPLAYS NOTHING

E-4 BACKLIGHT OF LCD UNIT ON MACHINE MONITOR IS ABNORMAL, (BACKLIGHT GOES OUT

OR FLICKERS)

E-5 LCD ON MACHINE MONITOR DOES NOT DISPLAY PROPERLY

E-6 METER UNIT DISPLAY ON MACHINE MONITOR IS ABNORMAL

E-7 NIGHT LIGHTING LAMP OF METER UNIT ON MACHINE MONITOR IS ABNORMAL

E-8 LED UNIT LAMP ON MACHINE MONITOR IS ABNORMAL

E-9 NIGHT LIGHTING LAMP OF SWITCH PANEL ON MACHINE MONITOR IS ABNORMAL OR

SWITCH DOES NOT OPERATE PROPERLY

E-10 2 SWITCHES OPERATION OF SWITCH PANEL ON MACHINE MONITOR DOES NOT FUNCTION

E-11 SWITCH PANEL BUZZER OF MACHINE MONITOR IS ABNORMAL

E-12 SOME ITEMS OF GAUGES AND CAUTION LAMPS ON MACHINE MONITOR ARE NOT DISPLAYED PROPERLY

E-13 REARVIEW MONITOR DOES NOT LIGHT UP OR BACKLIGHT FLICKERS

E-14 REARVIEW MONITOR IMAGES ARE NOT DISPLAYED CLEARLY

E-15 REARVIEW MONITOR BRIGHTNESS CANNOT BE ADJUSTED

E-16 NIGHT LIGHTING LAMP OF REARVIEW MONITOR IS ABNORMAL

E-17 REARVIEW MONITOR IS NOT DISPLAYED IN CONJUNCTION WITH REVERSE WHEN THE

CONSTANT DISPLAY SETTING IS DISABLED

E-18 REARVIEW MONITOR REFERENCE LINE IS NOT DISPLAYED WHEN THE REFERENCE LINE

DISPLAY SETTING IS ENABLED

E-19 FUEL LEVEL GAUGE DOES NOT INDICATE CORRECT LEVEL

E-20 SEAT BELT CAUTION LAMP INDICATION IS ABNORMAL

E-21 MACHINE MONITOR CANNOT BE OPERATED WHEN STARTING SWITCH IS IN OFF POSITION

E-22 ALARM BUZZER DOES NOT SOUND

E-23 ALARM BUZZER DOES NOT STOP SOUNDING

E-24 AISS FUNCTION DOES NOT OPERATE PROPERLY

E-25 HOIST LEVER DOES NOT OPERATE PROPERLY

E-26 TURN SIGNAL LAMP AND WINKER LAMP (HAZARD LAMP) DO NOT OPERATE PROPERLY

E-27 NONE OF HEADLAMP, CLEARANCE LAMP, AND TAIL LAMP LIGHTS

E-28 SMALL LAMP (CLEARANCE LAMP) DOES NOT LIGHT UP

E-29 TAIL LAMP DOES NOT LIGHT UP

E-30 HEADLAMP (LOW BEAM) DOES NOT LIGHT UP

E-31 HEADLAMP (HIGH BEAM) DOES NOT LIGHT UP

E-32 NEITHER (LOW BEAM) NOR (HIGH BEAM) HEADLAMPS LIGHTS UP

E-33 HIGH BEAMS DO NOT LIGHT UP WHILE PASSING SWITCH IS OPERATED

E-34 KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY

E-35 DATA DOWNLOADING BY USING WIRELESS LAN CAN NOT BE PERFORMED

E-36 KomVision MONITOR DOES NOT LIGHT UP OR BACKLIGHT FLICKERS

E-37 KomVision MONITOR IMAGES ARE NOT DISPLAYED CLEARLY

E-38 KomVision MONITOR BRIGHTNESS CANNOT BE ADJUSTED

E-39 NIGHT LIGHTING LAMP OF KomVision MONITOR IS ABNORMAL

E-40 PART OF THE CAMERA IMAGE IS NOT DISPLAYED ON THE KomVision MONITOR

E-41 IMAGE ON KomVision MONITOR IS NOT DISPLAYED PROPERLY AFTER CALIBRATION

E-42 EXTERNAL POWER SUPPLY ENGINE OIL PAN HEATER DOES NOT OPERATE

E-43 EXTERNAL POWER SUPPLY BRAKE TANK HEATER DOES NOT OPERATE

E-44 EXTERNAL POWER SUPPLY TRANSMISSION OIL PAN HEATER DOES NOT OPERATE

E-45 EXTERNAL POWER SUPPLY HYDRAULIC TANK HEATER DOES NOT OPERATE

E-46 BUZZER DOES NOT SOUND WHEN POWER LADDER IS OPERATED

E-47 POWER LADDER PUMP DOES NOT OPERATE

E-48 Cannot Access to the Setting Screen of the Mobile Communication Terminal

E-49 CANNOT LOG IN TO THE SETTING SCREEN OF THE MOBILE COMMUNICATION TERMINAL

BECAUSE THE LOG IN PASSWORD IS UNKNOWN

E-50 KOMTRAX Plus Controller is Not Found

E-51 KOMTRAX Plus Controller Does Not Become Active

E-52 Communication Failure Occurs Between Mobile Communication Terminal and KOMTRAX Plus

Server

E-53 Data is Not Sent to KOMTRAX Plus Server

Troubleshooting for Hydraulic and Mechanical Systems (H Mode)

INFORMATION MENTIONED IN TROUBLESHOOTING TABLE (H MODE)

FAILURE MODE AND CAUSE TABLE

H-1 MACHINE DOES NOT START

H-2 MACHINE DOES NOT TRAVEL SMOOTHLY (MACHINE HUNTS)

H-3 LOCKUP IS NOT RELEASED

H-4 ABNORMALLY STRONG SHOCKS RESULT FROM STARTING OF MACHINE AND GEAR

SHIFTING

H-5 GEAR IS NOT UPSHIFTED

H-6 MACHINE LACKS TRAVEL SPEED OR POWER WHEN TRAVELING IN LOCKUP DRIVE MODE

AT ALL GEAR SPEEDS

H-7 MACHINE LACKS TRAVEL SPEED OR POWER WHEN TRAVELING IN TORQUE CONVERTER

DRIVE MODE

H-8 MACHINE LACKS TRAVEL SPEED OR POWER WHEN TRAVELING AT PARTICULAR GEAR

SPEED

H-9 LARGE TIME LAG IS OBSERVED WHEN MACHINE STARTS AND GEAR IS SHIFTED

H-10 OIL TEMPERATURE OF TORQUE CONVERTER IS HIGH

H-11 OIL PRESSURE OF TORQUE CONVERTER IS LOW

H-12 STEERING WHEEL IS HEAVY TO OPERATE

H-13 STEERING WHEEL CANNOT BE OPERATED

H-14 STEERING WHEEL WAGGLES

H-15 FRONT BRAKE DOES NOT APPLY SUFFICIENTLY

H-16 REAR BRAKE DOES NOT APPLY SUFFICIENTLY

H-17 DUMP BODY RISING SPEED IS LOW

H-18 HYDRAULIC DRIFT OF DUMP BODY IS LARGE

H-19 DUMP BODY DOES NOT MOVE

H-20 FAN SPEED IS UNUSUAL (EXCESSIVELY HIGH OR LOW, OR FAN STOPS)

H-21 UNUSUAL NOISE IS HEARD FROM AROUND FAN

H-22 POWER LADDER DOES NOT MOVE OR ITS SPEED IS LOW

50 Disassembly and Assembly

Table of Contents

Precautions Before Work

Related Information on Disassembly and Assembly

HOW TO READ THIS MANUAL

COATING MATERIALS LIST

SPECIAL TOOL LIST

DIAGRAMS OF SPECIAL TOOLS

Engine and Cooling System

REMOVE AND INSTALL RADIATOR ASSEMBLY

REMOVE AND INSTALL OIL COOLER ASSEMBLY

REMOVE AND INSTALL ENGINE ASSEMBLY

REMOVE AND INSTALL DAMPER ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF DAMPER ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF RADIATOR ASSEMBLY

POWER TRAIN

REMOVE AND INSTALL FRONT DRIVE SHAFT

REMOVE AND INSTALL REAR DRIVE SHAFT ASSEMBLY

REMOVE AND INSTALL TORQUE CONVERTER AND TRANSMISSION ASSEMBLY

DISCONNECT AND CONNECT TORQUE CONVERTER AND TRANSMISSION ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF TORQUE CONVERTER AND PTO ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF TRANSMISSION ASSEMBLY

REMOVE AND INSTALL DIFFERENCIAL ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF DIFFERENTIAL ASSEMBLY

REMOVE AND INSTALL FINAL DRIVE CARRIER ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF FINAL DRIVE CARRIER ASSEMBLY

Brake System

REMOVE AND INSTALL FRONT WHEEL HUB AND BRAKE ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF FRONT WHEEL HUB AND BRAKE ASSEMBLY

REMOVE AND INSTALL FINAL DRIVE AND REAR BRAKE ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF FINAL DRIVE AND REAR BRAKE ASSEMBLY

Steering System

REMOVE AND INSTALL STEERING VALVE ASSEMBLY

REMOVE AND INSTALL O-RING OF STEERING VALVE ASSEMBLY

REMOVE AND INSTALL STEERING CYLINDER ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF STEERING CYLINDER ASSEMBLY

Undercarriage and Frame

REMOVE AND INSTALL FRONT WHEEL ASSEMBLY

REMOVE AND INSTALL REAR WHEEL ASSEMBLY

REMOVE AND INSTALL FRONT SUSPENSION CYLINDER ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF FRONT SUSPENSION CYLINDER ASSEMBLY (CYLINDER

WITH BUFFER RING)

REMOVE AND INSTALL KING PIN

REMOVE AND INSTALL REAR SUSPENSION CYLINDER ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF REAR SUSPENSION CYLINDER ASSEMBLY (CYLINDER

WITH BUFFER RING)

INSTALL AUTOMATIC FIRE EXTINGUISHER

Hydraulic System

REMOVE AND INSTALL FLOW AMPLIFIER VALVE ASSEMBLY

REMOVE AND INSTALL O-RING of FLOW AMPLIFIER VALVE ASSEMBLY

REMOVE AND INSTALL HOIST VALVE ASSEMBLY

REMOVE AND INSTALL HOIST CYLINDER HEAD ASSEMBLY

DISASSEMBLE AND ASSEMBLE OF HOIST CYLINDER ASSEMBLY

Work Equipment

REMOVE AND INSTALL DUMP BODY ASSEMBLY

CAB Related Parts

REMOVE AND INSTALL AIR CONDITIONER UNIT ASSEMBLY

REMOVE AND INSTALL OPERATOR'S SEAT ASSEMBLY

REMOVE AND INSTALL SEAT BELT

Electrical System

REMOVE AND INSTALL RETARDER AND HOIST CONTROLLER ASSEMBLY

REMOVE AND INSTALL TRANSMISSION CONTROLLER ASSEMBLY

REMOVE AND INSTALL MONITOR CONTROLLER ASSEMBLY

REMOVE AND INSTALL MACHINE MONITOR ASSEMBLY

REMOVE AND INSTALL KOMTRAX PLUS CONTROLLER ASSEMBLY

REMOVE AND INSTALL MOBILE COMMUNICATION TERMINAL

REMOVE AND INSTALL DC-DC CONVERTER

REMOVE AND INSTALL MOBILE COMMUNICATION TERMINAL WIRING HARNESS

REMOVE AND INSTALL KOMTRAX TERMINAL ASSEMBLY

REMOVE AND INSTALL REARVIEW CAMERA

REMOVE AND INSTALL KomVision CAMERA

REMOVE AND INSTALL KomVision RADAR

REMOVE AND INSTALL KomVision CONTROLLER ASSEMBLY

REMOVE AND INSTALL WIRELESS LAN UNIT ASSEMBLY

Remove and Install Driver Status Monitor

Remove and Install Translator Controller

Remove and Install Drowsiness Detection Camera

Remove and Install Drowsiness Alarm Buzzer

Remove and Install Drowsiness Detection Wiring Harness

60 Maintenance Standard

Table of Contents

Engine and Cooling System

MAINTENANCE STANDARD OF ENGINE MOUNT

MAINTENANCE STANDARD OF OUTPUT SHAFT

MAINTENANCE STANDARD OF FRONT BRAKE COOLING REMOTE MOTOR

MAINTENANCE STANDARD OF REAR BRAKE COOLING REMOTE MOTOR

Power Train

MAINTENANCE STANDARD OF DRIVE SHAFT

MAINTENANCE STANDARD OF TORQUE CONVERTER AND TRANSMISSION MOUNT

MAINTENANCE STANDARD OF TORQUE CONVERTER AND PTO

MAINTENANCE STANDARD OF TORQUE CONVERTER VALVE

MAINTENANCE STANDARD OF TORQUE CONVERTER REGULATOR VALVE

MAINTENANCE STANDARD OF TRANSMISSION

MAINTENANCE STANDARD OF TRANSMISSION CONTROL VALVE

MAINTENANCE STANDARD OF FORWARD AND REVERSE CLUTCH ECMV AND GEAR SPEED

CLUTCH ECMV

MAINTENANCE STANDARD OF LOCKUP CLUTCH ECMV

MAINTENANCE STANDARD OF TRANSMISSION LUBRICATION SELECTOR VALVE

MAINTENANCE STANDARD OF FRONT AXLE

MAINTENANCE STANDARD OF REAR AXLE

MAINTENANCE STANDARD OF DIFFERENTIAL

MAINTENANCE STANDARD OF FINAL DRIVE

Steering System

MAINTENANCE STANDARD OF STEERING COLUMN

MAINTENANCE STANDARD OF STEERING CONTROL LINKAGE

MAINTENANCE STANDARD OF STEERING CYLINDER

Brake System

MAINTENANCE STANDARD OF FRONT SLACK ADJUSTER

MAINTENANCE STANDARD OF REAR SLACK ADJUSTER

MAINTENANCE STANDARD OF FRONT BRAKE AND PARKING BRAKE

MAINTENANCE STANDARD OF REAR BRAKE AND PARKING BRAKE

Undercarriage and Frame

MAINTENANCE STANDARD OF FRONT SUSPENSION CYLINDER

MAINTENANCE STANDARD OF REAR SUSPENSION CYLINDER

MAINTENANCE STANDARD OF REAR AXLE SUPPORT

Hydraulic System

MAINTENANCE STANDARD OF STEERING AND HOIST PUMP

MAINTENANCE STANDARD OF DRIVE PUMP OF HOIST AND FRONT BRAKE COOLING REMOTE

MOTOR

MAINTENANCE STANDARD OF DRIVE PUMP OF REAR BRAKE COOLING REMOTE MOTOR

MAINTENANCE STANDARD OF SERVO VALVE OF DRIVE PUMP OF REAR BRAKE COOLING REMOTE MOTOR

MAINTENANCE STANDARD OF BRAKE CHARGE PUMP

MAINTENANCE STANDARD OF FRONT BRAKE COOLING AND POWER TRAIN TRIPLEX PUMP

MAINTENANCE STANDARD OF FRONT BRAKE COOLING REMOTE PUMP

MAINTENANCE STANDARD OF REAR BRAKE COOLING REMOTE TRIPLEX PUMP

Work Equipment

MAINTENANCE STANDARD OF HOIST CYLINDER

CAB Related Parts

MAINTENANCE STANDARD OF CAB MOUNT

80 Others

Table of Contents

Precautions Before Work

Air Conditioner System

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (7/11)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (8/11)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (9/11)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (10/11)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (11/11)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(1/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(2/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(3/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(4/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(5/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(6/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(7/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(8/9)

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (Only for machine with glass heater, additional heater)

(9/9)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (1/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (2/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (3/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (4/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (5/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (6/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (7/8)

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (8/8)

Electrical Circuit Diagram (Drowsiness Detection System (DDS))

Index