Link Belt 750X4 Service Manual WLSM7007-00LX

Size: 171.33 MB

Language: English

Machine: Excavator

Machine Model: 750X4

Part Number: WLSM7007-00LX

Publication Date: Dec. 2016

Pages: 2004 Pages

The Bookmarks of Link Belt 750X4 Excavator Service Manual WLSM7007-00LX Dec. 2016:

Excavator

SAFETY

Safety, general information and standard torque data

General Information

Standard Torque Data For Cap Screws And Nuts

A. LOWER

Main Equipment Table

Main Equipment Structure and Operation Explanation

Port Diagram

Basic Functions

Removal and Installation of Track

Removal and Installation of Shoe Assembly

Removal and Installation of Shoe Plate

Removal and Installation of Roller

Removal and Installation of Upper Roller

Assembly and Disassembly of Upper Roller

Removal and Installation of Lower Roller

Assembly and Disassembly of Lower Roller

Removal and Installation of Retractable Lower Frame

Removal and Installation of Drive Sprocket

Removal and Installation of Take-up Roller

Assembly and Disassembly of Take-up Roller

Removal and Installation of Grease Cylinder

Assembly and Disassembly of Grease Cylinder

Removal and Installation of Center Joint

Disassembly and Assembly of Center Joint

Removal and Installation of Travel Motor

Assembly and Disassembly of Travel Motor

Maintenance Standards

Pressure Measurement and Adjustment Procedures

Drain Volume Measurement Procedures

Air Bleed Procedure

B. C. SWING UNIT, COUNTERWEIGHT

Main Equipment Table

Counterweight Removal System (Option)

Main Equipment Structure and Operation Explanation

Port Diagram

Basic Functions

Removal and Installation of Swing Unit

Assembly and Disassembly of Swing Unit

Assembly and Disassembly of Swing Motor

Removal and Installation of Counterweight

Removal and Installation of Counterweight Removal System

Pressure Measurement and Adjustment Procedures

Drain Volume Measurement Procedures

Air Bleed Procedure

H. ENGINE

Main Equipment Table

Basic Functions

Main Data

Function, Structure, Operation

Function, Structure, and Operation of Emission Control

SCR Control System Inspection

Operation Explanation of SCR

Diagnosis for Each Symptom

Symptom

Functional Inspection

Removal and Installation of Engine Assembly

Removal and Installation of Fuel Cooler, Engine Intercooler, Radiator, and Oil Cooler

Removal and Installation of Turbo Charger

Removal and Installation of EGR Valve

Removal and Installation of EGR Cooler

Removal and Installation of Engine Hood

Removal and Installation of SCR

Removal and installation of Silicon Controlled Rectifier Catalyst

Removal and Installation of Cylinder Head Cover

Removal and Installation of Cylinder Block

Lubrication System

Cooling System

Induction System

Exhaust System

Aux. Emission Control Devices System

Removal and Installation of Fuel Tank

Removal and Installation of Urea Pump

Removal and Installation of Urea Solution Tank

Removal and Installation of Fuel Supply Pump

Removal and Installation of Common Rail Assembly

Removal and Installation of Injector

Removal and installation of Idle Gear

Removal and installation of Crankshaft

Removal and installation of Piston

Removal and installation of Camshaft

Removal and installation of Flywheel

Removal and Installation of Flywheel housing

Removal and Installation of Timing Gear Case

Removal and installation of Rocker Arm Shaft

Removal and installation of Intake Throttle Valve

Removal and Installation of Starter Motor

Removal and Installation of Alternator

Removal and Installation of Glow Plug

Removal and installation of Fuel Filter

Removal and installation of Relief Valve

Removal and installation of Fuel Filter Element

Removal and installation of Fuel temperature sensor

Removal and installation of Pressure limiter

Removal and installation of Fuel pressure sensor

Removal and Installation of Fuel filter pressure

Removal and Installation of Engine coolant temperature sensor

Removal and Installation of CKP sensor

Removal and Installation of CMP sensor

Removal and Installation of Oil Pressure Sensor

Removal and installation of Pressure Sensor/Boost Temperature Sensor

Removal and Installation of IMT sensor

Removal and installation of MAF and IAT sensor

Removal and installation of Charge Air Cooler Temperature Sensor 1

Sampling Procedure

Removal and Installation of Exhaust gas temperature sensor

Removal and installation of EGR Gas Temperature Sensor 1

Removal and installation of EGR Gas Temperature Sensor 2

Removal and installation of EGR Gas Temperature Sensor 3

Removal and installation of EGR Gas Temperature Sensor 4

Removal and installation of NOx Sensor

Removal and Installation of Exhaust gas temperature sensor 3

Removal and installation of DEF Sensor

Engine-related Diagnostic Trouble Code List

Engine-side Trouble

J. HYDRAULIC EQUIPMENT (PUMP, OPERATION SYSTEM VALVE)

Main Equipment Table

Basic Functions

Port Diagram

Hydraulic Pump

Hydraulically-operated fan pump

Hydraulically-operated fan motor

Control Valve

5 Stack Solenoid Valve Operation Explanation

Upper Pilot Valve (remote control valve)

Travel Pilot Valve (remote control valve)

Cushion Valve

Selector Valve (2-way)

Removal and Installation of Hydraulic Reservoir

Removal and Installation of Hydraulic Pump

Removal and Installation of Pump Coupling

Removal and Installation of Control Valve

Removal and Installation of Travel Remote Control Valve

Removal and Installation of Operation Remote Control Valve

Removal and Installation of 5 Stack Solenoid Valve

Removal and Installation of Cushion Valve

Removal and Installation of Hydraulically-Operated Fan Pump

Removal and Installation of Hydraulically-Operated Fan Motor

Procedures for Assembly and Disassembly of Hydraulic Pump Main Unit

Pump Main Unit Maintenance Standards

Regulator Maintenance Standards

Assembly and Disassembly of Control Valve

Assembly and Disassembly of Control Valve

Procedures for Assembly and Disassembly of Operation Remote Control Valve

Procedures for Assembly and Disassembly of Travel Remote Control Valve

Assembly and Disassembly of Cushion Valve

Pressure Measurement and Adjustment Procedures

Hydraulic Pump Flow Measurement Procedures

Air Bleed Procedure

Sampling Procedure

Hydraulic Equipment Layout

Overall View

N. CAB

Removal and Installation of Operator's Seat

Removal and Installation of Cab Assembly

Removal and Installation of Wiper

Removal and Installation of Cab Front Glass

Window Lock Adjustment Procedures

Removal and Installation of Housing Guardrail

Tightening Torque

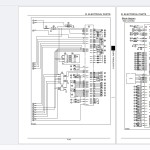

R. ELECTRICAL PARTS

Basic Functions

Service Support

Connection Connector Pin Layout

Sequence Circuit Diagram

Electrical Equipment Layout Diagram

Removal and Installation of Wiper Controller

Removal and Installation of Wiper Motor

Removal and Installation of ECM

Removal and Installation of Main Controller

Removal and Installation of DCU

Removal and Installation of Monitor

Removal and Installation of Rear View Camera

Removal and Installation of Side Camera (Right)

Removal and Installation of Side Camera (Left)

Removal and Installation of WAVES Controller

How to set WAVES

Air Conditioner Overall Diagram

Assembly and Disassembly of Unit

Removal and Installation of Compressor

Removal and Installation of Condenser

Removal and Installation of Receiver Dryer

Work Precautions

V. ATTACHMENTS

Main Equipment Table

Maintenance Standards

Removal and Installation of Bucket Cylinder

Removal and Installation of Arm Cylinder

Removal and Installation of Boom Cylinder

Procedures for Operation/Assembly and Disassembly of Hydraulic Cylinder

Port Diagram

Air Bleed Procedure

Removal and Installation of HBCV

Removal and Installation of Arm HBCV

Removal and Installation of Boom HBCV

Removal and Installation of Bucket

Removal and Installation of Bucket Link

Removal and Installation of Arm

Removal and Installation of Boom

Z. OTHER

Changes from Model -5

Specifications (750X4)

Specifications (750X4) (Large Soil Volume)

Arm Dimension

Main Unit Weight

Bolt Size and Torque Table

Overall View

WORK RANGE DIAGRAM

FLUIDS AND LUBRICANTS

Main-unit-related Diagnostic Trouble Code List

Main Unit-side Trouble

List of special tools

Abbreviation

Disassembly and Assembly