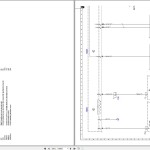

Mercedes C-Class W205 2014-2018 Workshop Manual Wiring Diagram

Size: 158.48 MB

Brand: Mercedes

Machine: Automotive

Document: Workshop Manual and Wiring Diagram

Machine Model: Mercedes C-Class W205

Publication Date: 2014-2018

Page: 3693 Pages

Contents:

Cover

00 Overall Vehicle

Abbreviations of signal and circuit designations for wiring diagrams

Active brake booster

Advantages of repairing wiring harnesses

Check gear capacity

Checking wiring harness

Clean evaporator and air conditioning system on inside

Connect STAR DIAGNOSIS and read out fault memory

Connect STAR DIAGNOSIS and read out fault memory1

Connect STAR DIAGNOSIS and read out fault memory3

Discontinuation of automatic child seat recognition, replaced by seat occupation mat

Double flat spring female contact, contact family

Dry braking

E 95 contact family

Exclusion of liability for third-party retrofits, form

Exterior mirror parking position

Female connectors

General repair methods for wiring harness

Interior cleaning

Junior Power Timer contact family

Lamella contact system 1.5 connector family

Lift jack up vehicle

Lift jack up vehicle1

Location and assignment of ground points

Location and assignment of line and plug connectors

Location and assignment of Z connector sleeves (wiring and plug connectors in wiring harness)

Location of left engine compartment ground points

Maxi Power Timer contact family

Micro quadlock system contact family

Micro quadlock system contact family1

Micro Timer 3 contact family

Mini lamella contact connector family

Miniature double flat spring female contact, contact family

Multi-Contact-Point contact family

Noises when turning steering to the limit stop

Notes on avoiding damage through contamination and foreign objects

Notes on crimping

Notes on replacement of safety-relevant and special components

Notes on replacement of safety-relevant and special components1

Notes on replacement of safety-relevant and special components2

Notes on replacement of safety-relevant and special components3

Notes on replacement of safety-relevant and special components4

Notes on replacement of safety-relevant and special components5

Notes on replacement of safety-relevant and special components6

Notes on soft soldering

Notes on soldering

Notes on the use of paint scraping nuts on ground connections

Notes regarding plug connections

Notes regarding plug connections1

Notes regarding plug connections2

Notes regarding plug connections3

Notes regarding plug connections4

Notes regarding plug connections5

Notes regarding plug connections6

Overview of innovations changes

Protect repair area after cable repairs

Regular cleaning of climate control system

Remove contacts from 2.5 plug round plug contact

Remove contacts from 2.5 round plug contact coupling

Remove contacts from 2.5 solder contact coupling round plug contact

Remove contacts from 2.5 solder contact plug round plug contact

Remove contacts from FIN sensor contact connector

Remove contacts from FIN sensor contact coupling

Remove contacts from FIN sensor contact coupling1

Remove contacts from FIN sensor contact coupling2

Remove contacts from Junior Power Timer coupling

Remove contacts from Junior Power Timer coupling1

Remove contacts from Junior Power Timer coupling2

Remove contacts from Junior Power Timer coupling3

Remove contacts from laminated contact system coupling

Remove contacts from laminated contact system plug

Remove contacts from maxi power timer coupling

Remove contacts from maxi power timer coupling1

Remove contacts from micro quadlock system coupling

Remove contacts from micro quadlock system coupling1

Remove contacts from micro quadlock system coupling2

Remove contacts from Micro Timer 3 coupling

Remove contacts from Micro Timer 3 coupling1

Remove contacts from Multi Contact Point (MCP) coupling

Remove contacts from Multi Contact Point (MCP) coupling1

Remove contacts from sensor laminated contact coupling

Remove contacts from Siemens ELO connector

Remove contacts from Siemens ELO coupling

Remove contacts from standard power timer connector

Remove contacts from standard power timer coupling

Remove contacts from YAZAKI 1.5 system coupling

Remove female contact from double flat spring contact coupling

Remove female contact from miniature double flat spring contact coupling

Removing contacts from plugs and connectors

Removing contacts from plugs and connectors1

Repair cable harness using rapid connection technology

Repair flat conductor wiring harness by crimping

Repair wiring harness by crimping (with watertight connections)

Repair wiring harness by crimping

Repair wiring harness by means of axial solder connectors

Repair wiring harness with line cross-section of 0.13 mm2 using axial solder connector

Repairing cable harness by soldering

Repairing wiring harness using solder connectors

Retrofit Adaptive Highbeam Assist Plus

Retrofit Adaptive Highbeam Assist

Retrofit rain sensor of windshield wiper system

Retrofit Speed Limit Assist

Risk of accident from vehicle starting off by itself when engine running

Risk of death caused by body parts being pulled in by rotating vehicle wheels and roller dynamometer rollers

Risk of injury caused by fingers being jammed or pinched when removing, installing or aligning hoods, doors, trunk lid rear-end door

Round plug contact 2.5 variant 1 connector family

Round-type contact 2.5 solder contact connector family

Secure vehicle on vehicle lift

Secure vehicle on vehicle lift1

Secure vehicle on vehicle lift2

Sensor laminated contact, connector family

Sensor laminated contact, contact family

Sensor laminated contact, contact family1

Service Information AMG After Sales Portal

Service Information AMG After Sales Portal1

Service Information Auxiliary materials for vehicle maintenance and repair

Service Information Auxiliary materials for vehicle maintenance and repair1

Service Information bulletin Specifications for Operating Fluids for automatic transmission

Service Information Content and application of data mediums Telematics

Service Information Damage or breakdown case in international traffic

Service information Dying of windshield washer fluid concentrate

Service Information Exclusion of liability for third-party retrofits

Service Information Exclusion of liability for third-party retrofits1

Service Information Forms for delivery and hand-over inspections, inspections and checks in information type AP

Service information Fuel level indicator

Service Information Introduction of GOTIS (GSP Online Technics Information System)

Service Information Invoicing of quick test

Service Information Maintenance interval

Service Information Multipurpose metal grease

Service information New damage code

Service Information New features modifications in passenger cars

Service Information New operation number structure for diagnosis jobs

Service Information New operation number structure for diagnosis jobs1

Service information New update concept for diagnosis applications

Service information Online access to GSP-TI Shop for ordering customer and workshop literature

Service Information Operation items for test drives

Service Information Operation items for test drives1

Service Information PARKTRONIC malfunctions

Service Information Processing of warranty and goodwill claims

Service Information Processing of warranty and goodwill claims1

Service Information QR code for rescue forces

Service Information QR code for rescue forces1

Service Information Responsibilities within the framework of the After Sales standards

Service Information SDconnect rechargeable battery

Service Information Service kit for rectifying squeaking, creaking and tearing noises

Service Information Software-based retrofits

Service Information Software-based retrofits1

Service Information Structure of the new operation numbers for SmallRepair in ASRA

Service Information Trouble diagnosis bulletins (AF) publication type not applicable

Service Information Vehicle identification plate orders

Service information Wiping quality and noise development

Service Information WIS Service Media

Service-Information Xentry Support & Feedback in WIS net

Siemens ELO contact family

Standard Power Timer contact family

Suspension characteristics

Temperature-dependent lowering of vehicle level

Use of wiring diagrams

Windshield washer system

Windshield

Wiper arm

Wiper blade

YAZAKI 1.5 system connector family

01 Complete engine, crankcase ventilation, cylinder head, crankcase

Bolt plan for timing case cover

Bolt tightening procedure for cylinder head cover

Bolt tightening procedure for cylinder head cover1

Check cylinders for leaks

Check cylinders for leaks1

Connect cylinder leakage testing unit

Connect cylinder leakage testing unit1

Connecting recording-type compression tester

Crank engine with starter

Disconnect engine wiring harness

Disconnect engine wiring harness1

Firing order

General information on inspecting cylinder walls

Inspect cylinders with a light probe

Notes on sealant path for cylinder head cover

Notes on sealant path for front cover to cylinder head xxx

Notes on sealant path for oil pan

Notes on sealant path for timing case cover

Remove install cylinder head cover

Remove install cylinder head cover1

Remove install cylinder head

Remove install cylinder head1

Remove install engine with transmission

Remove install front cover on cylinder head

Remove install front cover on cylinder head1

Remove install oil pan

Remove install oil pan1

Remove install oil separator

Remove install oil separator1

Remove install oil separator2

Remove install timing case cover

Remove install timing case cover1

Remove sealant

Replace full load housing ventilation

Replace full load housing ventilation1

Replace full load housing ventilation2

Test compression pressure

Tightening procedure for cylinder head bolts

Tightening procedure for cylinder head bolts1

03 Crank assembly

Install front crankshaft radial seal

Installing rear crankshaft radial sealing ring

Installing rear crankshaft radial sealing ring1

Measure tilt and torsional play on two-mass flywheel

Move Lanchester balance shaft to basic position

Remove install belt pulley vibration damper

Remove install belt pulley vibration damper1

Remove install flywheel drive plate

Remove install flywheel drive plate1

Remove install Lanchester balancer

Remove install retaining lock for crankshaft ring gear

Remove install retaining lock for crankshaft ring gear1

Remove install retaining lock for crankshaft ring gear2

Replace front crankshaft radial sealing ring

Replacing rear crankshaft radial seal

Replacing rear crankshaft radial seal1

05 Engine timing

Check basic position of camshafts

Check hydraulic valve clearance compensating elements

Disconnect timing chain

Draw in timing chain

Remove install camshafts

Remove install camshafts1

Remove install camshafts2

Remove install camshafts3

Remove install chain tensioner

Remove install chain tensioner1

Remove install chain tensioner2

Remove install chain tensioner3

Remove install hydraulic valve clearance compensating elements

Remove install hydraulic valve clearance compensating elements1

Remove install slide rail of timing chain

Remove install solenoid camshaft

Remove install solenoid camshaft1

Remove install solenoid camshaft2

Remove install tensioning rail

Remove install tensioning rail1

Remove install valve lift switchover actuator

Remove install valve springs and or valve stem seals

Remove install valve springs and or valve stem seals1

Remove install valve springs and or valve stem seals2

Remove install valve springs and or valve stem seals3

Remove install valves

Remove install valves1

Replace timing chain

Replace valve stem seals

Replace valve stem seals1

Replace valve stem seals2

Rivet timing chain

Set basic position of camshafts

Set basic position of camshafts1

Set basic position of camshafts2

07 Mixture information

Check fuel high pressure circuit.

Check high-pressure lines

Check high-pressure lines1

Exhaust emission test I

General information on work on gasoline direct injection system

General information on work on gasoline direct injection system1

General

Mount high-pressure lines.

Program ME-SFI (ME) control unit (code 1403P54A82)

Rail tightening procedure

Reduce fuel pressure through service valve

Reduce fuel pressure through service valve1

Relieve fuel pressure

Relieve fuel pressure1

Remove injection nozzles

Remove injection nozzles1

Remove install a pressure sensor

Remove install for NOx temperature sensor for storage catalytic converter

Remove install fuel injectors sealing package on rail

Remove install fuel injectors

Remove install heated O2 sensor

Remove install high-pressure pump

Remove install injection system control unit

Remove install NOx sensor

Remove install pressure transducer for boost pressure control

Remove install rail

Remove install rail1

Remove install throttle valve actuator

Replace fuel injector sealing ring

Replace fuel injector sealing ring1

Service Information on fuel consumption measurement

Service Information Program ME-SFI control unit

Test and adjustment values for exhaust emission test I

Test and adjustment values for exhaust emission test I1

Test and adjustment values for exhaust emission test I2

Test and adjustment values for exhaust emission test I3

Test and adjustment values for exhaust emission test I4

Test and adjustment values for exhaust emission test I5

Test and adjustment values for exhaust emission test I6

Test and adjustment values for exhaust emission test I7

Test and adjustment values for exhaust emission test I8

Test and adjustment values for exhaust emission test I9

Test and adjustment values for exhaust emission test I10

Test and adjustment values for exhaust emission test I11

Test and adjustment values for exhaust emission test I12

Test and adjustment values for exhaust emission test I13

Test and adjustment values for exhaust emission test I14

Test and adjustment values for exhaust emission test I15

Test and adjustment values for exhaust emission test I16

Test and adjustment values for exhaust emission test I17

Test and adjustment values for exhaust emission test I18

Test and adjustment values for exhaust emission test I19

Test and adjustment values for exhaust emission test I20

Test and adjustment values for exhaust emission test I21

Test and adjustment values for exhaust emission test I22

Test sheet for fuel consumption measuring drive, form

Tightening procedure for high-pressure pump shielding

Tightening procedure for high-pressure pump shielding1

Wiring diagram for gasoline direct injection system control unit

09 Air intake, turbocharging

Check low-temperature circuit cooling system for leaks

Check low-temperature circuit cooling system for leaks1

Drain fill low-temperature circuit coolant

Drain fill low-temperature circuit coolant1

Notes on installing air intake hose on turbocharger

Open and close coupling

Remove install air filter housing

Remove install air filter housing1

Remove install air intake pipe

Remove install air intake pipe1

Remove install air intake pipe2

Remove install air intake pipe3

Remove install charge air cooler, water-cooled

Remove install charge air cooler, water-cooled1

Remove install charge air manifold

Remove install circulation pump for low-temperature water circuit

Remove install engine intake air duct downstream of air filter

Remove install low-temperature circuit expansion reservoir

Remove install low-temperature circuit expansion reservoir1

Remove install the coolant lines for the turbocharger

Remove install the oil line on the turbocharger

Remove install turbocharger with exhaust manifold

Tightening procedure for charge air manifold

13 Air compressor, belt drives

Remove install drive belt component

Risk of injury. Skin or eye injuries may result when handling hot or glowing objects.

Routing diagram for poly-V belt

14 Exhaust manifold, engine brake, emission control

Electrical function schematic for exhaust gas recirculation

Electrical function schematic for exhaust treatment

Electrical function schematic for exhaust treatment1

Install, remove exhaust gas recirculation

Install, remove exhaust gas recirculation1

Install, remove exhaust gas recirculation2

Install, remove exhaust gas recirculation3

Remove install exhaust gas recirculation (AGR) differential pressure sensor

Remove install exhaust gas recirculation (AGR) differential pressure sensor1

Remove install exhaust gas recirculation cooler

Remove install exhaust gas recirculation valve

Service Information Fill AdBlue container

Service Information Return delivery of AdBlue tank

15 Electrical system Engine

Component description for the alternator

Component description for the alternator1

Disconnecting and connecting harness at starter

Notes on avoiding damage to ignition system

On-board electrical system power supply Location of components

On-board electrical system power supply, function

On-board electrical system power supply, function1

On-board electrical system power supply, function2

Overview of system components On-board electrical system power supply

Power supply for on-board electrical system, location of components

Power supply for on-board electrical system, location of components1

Power supply for on-board electrical system, location of components2

Power supply for on-board electrical system, location of components3

Remove install alternator belt pulley

Remove install alternator

Remove install alternator1

Remove install alternator2

Remove install camshaft Hall sensor

Remove install coolant temperature sensor

Remove install crankshaft Hall sensor

Remove install crankshaft Hall sensor1

Remove install crankshaft pulse ring

Remove install ignition coils

Remove install knock sensors

Remove install starter

Risk of death caused by contact with parts conducting high voltages.

Service Information Alternator diagnosis

Service information Alternator diagnosis1

Service Information Diagnosis on ignition system

Service Information Return delivery of starter diagnostic data

Service Information Return of diagnostic data when replacing the alternator or alternator regulator

Table of contents for function description On-board electrical system power supply

Wiring diagram for Start Stop engine

Wiring diagram for Start Stop engine1

Wiring diagram for Start Stop engine2

Wiring diagram of starter, alternator, battery

18 Engine lubrication, engine oil cooling

Check engine oil level using on-board oil dipstick

Check oil pressure

Engine oil and filter change

Engine oil and filter change1

Maintenance intervals in combination with oils as per MBBV sheet, general overview

Notes on engine oil and filter changes

Overview - Check engine oil level

Remove install oil dipstick guide tube

Remove install oil dipstick guide tube1

Remove install oil level check switch

Remove install oil pump

Remove install oil-water heat exchanger

Replace seal on oil dipstick guide tube

Risk of injury to skin and eyes due to handling of engine oil. Risk of poisoning caused by swallowing engine oil

Service Information Engine oil change

Service Information Engine oil change1

Service Information Engine oil change2

Service Information Oil filter housing

20 Engine cooling system

Drain pour in coolant

Drain pour in coolant1

Inspect cooling system for leaks

Inspect cooling system for leaks1

Inspect cooling system for leaks2

Notes on coolant

Open, close coolant line coupling

Pour in coolant and bleed cooling system

Pour in coolant and bleed cooling system1

Pour in coolant and bleed cooling system2

Remove install coolant pump

Remove install coolant thermostat

Remove install electric coolant pump

Remove install electric coolant pump1

Remove install expansion reservoir

Remove install fan unit

Remove install fan unit1

Remove install radiator

Remove nstall coolant line

Risk of injury to skin and eyes suffering scalding from contact with hot coolantspray. Risk of poisoning from swallowing coolant.

Service Information Coolant

22 Engine suspension

Remove install engine mount or engine crossmember at the rear

Remove install front engine mount and or engine support

27 Automatic transmission

Check adjust axial play between shim and circlip

Check adjust axial play between shim and circlip1

Check oil level in automatic transmission and correct if necessary.

Detach attach torque converter on driver

Detach attach torque converter on driver1

Detach attach torque converter on driver2

Detach attach transmission housing on torque converter housing.

Detach attach transmission housing on torque converter housing

Detach mount start-up clutch on driven plate

Differential lock control unit wiring diagram

Differential lock control unit wiring diagram1

Disassemble and assemble electrohydraulic controller unit

Disassemble assemble K2 clutch

Disassemble assemble K3 clutch

Disassemble assemble K3 clutch1

Disassemble assemble multi-disk brake B1

Disassemble assemble multi-disk brake B3

Disconnect connect plug connection

Dismantle and assemble rear tubular shaft

Dismantle and assemble rear tubular shaft1

Dismantling and assembling clutch K1

Dismantling and assembling clutch K1-1

Electrical function schematic for shift operation

Electrical function schematic for shift operation1

Electrical function schematic, fully integrated transmission control

Electrical function schematic, Key-P

End disk modified

Fasten transmission on assembly stand

Fasten transmission on assembly stand1

Fasten transmission on assembly stand2

Filling automatic transmission with fluid

Filling automatic transmission with fluid1

Filling automatic transmission with fluid2

Filling automatic transmission with fluid3

Flush out automatic transmission and torque converter

Flushing out oil cooler lines and oil cooler

Flushing out oil cooler lines and oil cooler1

Insert selector valve into driver of detent plate

Install grooved ball bearing in rear transmission housing

Install grooved ball bearing in rear transmission housing1

Locking plate of shift rod on intermediate lever modified

Measure and adjust clearance in multidisk brake BR

Measure and adjust clearance

Measure end play between park pawl gear and grooved ball bearing

Measure end play between park pawl gear and grooved ball bearing1

Measure end play between park pawl gear and grooved ball bearing2

Notes on automatic transmission

Notes on automatic transmission1

Oil pan and overflow tube modified

Oil pan and overflow tube modified1

Oil pan and overflow tube modified2

Remove grooved ball bearing in rear transmission housing

Remove grooved ball bearing in rear transmission housing1

Remove insert start-up clutch

Remove install and set shift rod

Remove install automatic transmission fluid cooler

Remove install automatic transmission oil pan

Remove install automatic transmission oil pan1

Remove install automatic transmission oil pan2

Remove install automatic transmission

Remove install automatic transmission1

Remove install automatic transmission2

Remove install automatic transmission3

Remove install auxiliary oil pump for automatic transmission

Remove install clutch pack BR, multidisk brake B2 and park pawl gear

Remove install clutch pack BR, multidisk brake B2 and park pawl gear1

Remove install control solenoid valves of electric controller unit

Remove install control solenoid valves of electric controller unit1

Remove install electrohydraulic controller unit (transmission installed)

Remove install intelligent servo module

Remove install K3, rear hollow shaft, rear planet carrier and output shaft

Remove install K3, rear hollow shaft, rear planet carrier and output shaft1

Remove install K3, rear hollow shaft, rear planet carrier and output shaft2

Remove install lines at automatic transmission

Remove install main components of transmission

Remove install main components of transmission1

Remove install multi-disk brake B1 and oil pump

Remove install multi-disk brake B1 and oil pump1

Remove install oil lines of oil cooling for automatic transmission

Remove install oil lines of oil cooling for automatic transmission1

Remove install oil pump radial shaft sealing ring

Remove install park pawl mechanism

Remove install radial shaft sealing ring at output flange

Remove install radial shaft sealing ring on front transmission cover

Remove install shield at transmission

Remove install shield at transmission1

Remove install torque converter

Remove install torque converter1

Remove install torque converter2

Remove install torque converter3

Remove install transmission with torque converter

Remove install transmission with torque converter1

Remove install transmission with torque converter2

Remove install transmission with torque converter3

Remove install transmission with torque converter4

Remove install transmission with torque converter5

Remove install transmission with torque converter6

Remove install transmission with torque converter7

Remove install transmission with torque converter8

Remove install transmission with torque converter9

Remove install transmission with torque converter10

Remove install transmission with torque converter11

Remove install transmission with torque converter12

Remove install transmission with torque converter13

Removing and installing output flange

Removing and installing output flange1

Removing and installing output flange2

Removing installing drive shaft with K2, front planet carrier, internal plate carrier with K1 and B3

Removing installing drive shaft with K2, front planet carrier, internal plate carrier with K1 and B31

Removing installing drive shaft with K2, front planet carrier, internal plate carrier with K1 and B32

Service Information Adaptation of automatic transmission shift operations

Service Information Additional adaptation counter indicator

Service Information Introduction of the 722.9 (7G-Tronic) automatic transmission

Service information Operation items

Wiring diagram for fully integrated transmission control unit

Wiring diagram for intelligent servo module (ISM) control unit

Wiring diagram for transmission oil auxiliary pump control unit

29 Pedal assembly

Information on preventing damage to electronic components due to electrostatic discharge

Remove install pedal assembly

30 Throttle control, speed control systems

Distronic PLUS electrical function schematic

Electrical function schematic for BAS PLUS

Electrical function schematic for BAS PLUS1

Electrical function schematic for cruise control (CC)

Electrical function schematic for cruise control (CC)1

Electrical function schematic for DISTRONIC PLUS with Steer Assist and Stop & Go Pilot

Electrical function schematic for electronic accelerator

Electrical function schematic for PRE-SAFE brake

Electrical function schematic for PRE-SAFE rear

Remove install accelerator pedal

Remove install Distronic sensor (DTR)

Remove install radar sensor

Remove install radar sensor1

Service Information Warranty and goodwill policy for short-range radar sensors

Wiring diagram for COLLISION PREVENTION ASSIST control unit

Wiring diagram for the radar sensors control unit

Wiring diagram for the radar sensors control unit1

Wiring diagram for the radar sensors control unit2

Wiring diagram for the radar sensors control unit3

Wiring diagram of Distronic (DTR) control unit

31 Frame, trailer operation

Perform function check on trailer hitch with electrical release

Perform function check on trailer hitch with electrical release1

Performing function test of light signals at trailer coupling socket

Remove install left trailer hitch longitudinal member

Remove install right trailer hitch longitudinal member

Remove install trailer hitch crossmember

Remove install trailer hitch crossmember1

Remove install trailer hitch socket housing

Remove install trailer hitch

Remove install trailer recognition control unit

Trailer coupling socket wiring harness, removal and installation

Trailer coupling socket wiring harness, removal and installation1

Trailer recognition control unit wiring diagram

32 Suspension

Check AIRmatic for leaks.

Check function of headlamp range adjustment

Checking shock absorber

Checking shock absorber1

Checking supporting joint and follower joint of steering knuckle mount (removed)

Clamping rear spring

Connect STAR DIAGNOSIS and read out fault memory

Disassemble assemble suspension strut

Disassemble assemble suspension strut1

Disconnect connect battery ground line

Electrical function schematic for adaptive damping system (ADS)

Electrical function schematic for Airmatic

Inspect front axle joint for play, inspect rubber boots

Install remove emergency buffer

Lift jack up vehicle

Locate noises from the suspension

Notes on AIRmatic 1

Notes on AIRmatic

Notes on AIRmatic2

Notes on pedestrian protection sensor

Notes on sensor system for trunk lid opening closing

Perform wheel alignment check

Pressing out and attaching follower joint at steering knuckle 1

Pressing out and attaching follower joint at steering knuckle

Remove install additional battery

Remove install air spring

Remove install air suspension control unit

Remove install air suspension valve unit

Remove install air suspension valve unit1

Remove install air suspension valve unit2

Remove install bracket for compressor

Remove install bracket for compressor1

Remove install compressor

Remove install compressor1

Remove install compressor2

Remove install door sill molding

Remove install follower joint of steering knuckle bearing

Remove install front floor covering (right)

Remove install front stabilizer bar link rod

Remove install front stabilizer bar link rod1

Remove install rear shock absorber

Remove install spring control arm on front axle

Remove install stabilizer bar on front axle

Remove install stabilizer bar on front axle1

Remove install stabilizer bar on front axle2

Remove install stabilizer bar on front axle3

Remove install the suspension strut

Remove install the suspension strut1

Remove install the suspension strut2

Remove install the suspension strut3

Remove install the suspension strut4

Remove install the suspension strut5

Remove install torsion bar on rear axle

Remove install upper control arm

Remove install upper control arm1

Remove install upper control arm2

Repairing AIRmatic pressure line connection

Repairing AIRmatic pressure line connection1

Repairing AIRmatic pressure line connection2

Repairing AIRmatic pressure line connection3

Replace rubber mount for compressor

Replace rubber mount for compressor1

SI Assembly of suspension struts and shock absorbers

SI Replacement of shock absorbers

Upper transverse control arm modified

Wiring diagram for adaptive damping system (ADS) control unit

Wiring diagram of AIRmatic control unit

33 Front axle

Attach engine hoist

Attach engine hoist1

Checking follower joint of steering knuckle mount (installed)

Insertion extraction of the rubber bushing on the track control arm

Locate noises from the front axle

Lower front axle

Remove install front axle half

Remove install front axle

Remove install spring control arm on front axle

Remove install steering knuckle

Remove install torque strut at front axle

Remove install upper control arm

Remove install upper control arm1

Remove install wheel bearing

Remove install wheel bearing1

35 Rear axle

Check rear axle differential oil level, correct if necessary

Check rear axle differential oil level, correct if necessary1

Clean water drain in wheel carrier

Disassemble check for wear assemble constant velocity joint of splined rear axle shaft

Locate noises from rear axle

Lower rear axle.

Lower rear axle1

Press off press on caulk joint hub of splined rear axle shaft

Pressing out and drawing in rear axle shaft at rear axle shaft flange

Remove install camber strut

Remove install complete rear axle

Remove install constant velocity joint or boot of splined rear axle shaft

Remove install cup seal on joint ring of splined rear axle shaft

Remove install cup seal on joint ring of splined rear axle shaft1

Remove install cup seal on joint ring of splined rear axle shaft2

Remove install front and rear rubber bushings in rear axle mount

Remove install front differential mount on rear axle carrier

Remove install front rubber mount in rear axle mount

Remove install inserted rear axle shaft

Remove install inserted rear axle shaft1

Remove install radius rod

Remove install rear axle shaft flange and angular ball bearing

Remove install rear axle shaft flange and angular ball bearing1

Remove install rear rubber bushings for differential mount in rear axle carrier

Remove install rear rubber mount in rear axle mount

Remove install rear rubber mount of rear axle center assembly suspension

Remove install rubber mounts from thrust arm

Remove install spring control arm rubber mount

Remove install spring control arm, replace rubber bushing

Remove install supporting joint at wheel carrier (wheel carrier installed)

Remove install supporting joint at wheel carrier (wheel carrier installed)1

Remove install supporting joint on wheel carrier

Remove install thrust arm

Remove install track rod

Remove install wheel carrier

Remove install wheel carrier1

Replace radial sealing rings on side of rear axle center assembly

Replace radial sealing rings on side of rear axle center assembly1

Replace radial sealing rings on side of rear axle center assembly2

Service Information Repair information on self-locking threaded connections at the axle mounts

40 Wheels, chassis alignment check

Adjust camber and caster at the front axle

Adjust front axle toe

Adjust rear-axle toe

Attaching Mercedes-Benz quick-clamping devices

Balancing wheels

Carry out conditions and tests for chassis alignment

Carry out distance and comparison measurements on front and rear axles

Caster values, form

Check tires for damage and crack formations

Check tires for damage and crack formations1

Check toe-out angle

Check vehicle level at front and rear axle with electronic inclinometer, adjust if necessary

Checking rear axle camber

Checking tires for lateral and radial runout

Clean check corrosion protect wheel bolting components

Correct tire inflation pressure

Correct tire inflation pressure1

Draining TIREFIT sealant out of tires

Electrical function schematic for tire pressure loss warning (RDW) system

Electrical function schematic for tire pressure monitor (TPM (RDK))

General information on vehicle level measurement

General overview of approved wheel tire combinations, as-built configuration

Information on tires rims

Information on tires rims1

Mounting centering sleeve

Notes on tire flat spots

Perform smooth operation optimization

Perform wheel alignment check

Remove install tire pressure monitoring system control unit

Remove install wheel sensor

Remove install wheels, rotate if necessary

Remove install wheels

Remove install wheels1

Replace tires

Replace tires1

Service Information bulletin TIREFIT tire sealant

Service information Changing wheels tires

Service Information Clean light alloy disk wheel

Service Information Cosmetic processing of light alloy wheels

Service Information Permissible valve caps for vehicles with tire pressure monitoring system

Service Information Use of nitrogen as a tire-filling gas

TIREFIT tire sealant

Wiring diagram for tire pressure monitor control unit

41 Propeller shaft

Check propeller shaft flex disks for signs of damage and deformation

Connect sections of propeller shaft

Connect sections of propeller shaft1

Connect sections of propeller shaft2

Measure propeller shaft alignment with electronic propeller shaft inclinometer

Press grooved ball bearing out of rubber mount of propeller shaft, press in

Press in pilot bushing

Press rubber mount with grooved ball bearing onto linkage arm

Pulling off rubber mount with grooved ball bearing

Pulling off rubber mount with grooved ball bearing1

Remove install flexible coupling of drive shaft at transmission end

Remove install propeller shaft intermediate bearing and replace grooved ball bearing

Remove install propeller shaft intermediate bearing and replace grooved ball bearing1

Remove install propeller shaft

Remove install propeller shaft1

Remove pilot bushing

Replace pilot bushing

42 Brakes hydraulic and mechanical

Assess condition of brake disks

Bleed brake system

Brake fluid notes

Brake system - inspect fluid level

Brake system - inspect fluid level1

Brake test

Carrying out bleeding operation

Check brake system for leaks

Check brake system for leaks1

Detach mount connector

Electrical function schematic for Adaptive Brake (ABR)

Electrical function schematic for electric parking brake

Electrical function schematic for electric parking brake1

Locate noises from the brake

Move rear axle brake pads to assembly position

Move rear axle brake pads to assembly position1

Notes on accident prevention on the brake roller dynamometers T2 model 668-670 with air-pressure power braking

Notes on externally invisible brake fluid loss

Notes on handling, transport and storage of ceramic brake disks

Notes on handling, transport and storage of composite brake disks

Notes on installing brake wear indicator contact sensors

Notes on repairs to brake system

Remove check install front axle brake pads

Remove check install rear axle brake pads

Remove install brake disc

Remove install brake disc1

Remove install brake disc2

Remove install electric parking brake actuator motor

Remove install electric parking brake actuator motor1

Remove install electric parking brake switch

Remove install ETS ASR ESP hydraulic unit

Remove install front axle brake caliper

Remove install front axle brake caliper1

Remove install left front or right rpm sensor

Remove install left or right rear axle speed sensor

Remove install master brake cylinder

Remove install mechanical stop lamp switch

Remove install pulse ring

Remove install rear axle brake caliper

Remove install rear axle brake caliper1

Removing and installing brake fluid reservoir

Removing and installing brake fluid reservoir1

Replace brake hoses

Replace brake lines

Risk of poisoning from swallowing brake fluid. Risk of injury from skin and eye contact with brake fluid

Service Information Brake caliper with Mercedes-Benz brand cover

Service Information Brake lining installation instructions

Test brake system with pressure tester for leaks

Wiring diagram for Adaptive Brake (ABR)

Wiring diagram for Adaptive Brake (ABR)1

Wiring diagram for electric parking brake

43 Brakes pneumatic

Checking brake booster

Checking check valve

Connect disconnect testing unit at brake booster

Connect disconnect testing unit at brake booster1

Remove install brake booster vacuum line

Remove install vacuum pump

46 Steering

Check and replace rubber boot

Check and replace rubber boot1

Check replace water drain valve in steering gear

Electrical function schematic for easy entry exit steering column adjustment

Electrical function schematic for electric power steering

Electrical function schematic for steering column adjustment

Electronic ignition starter switch (EZS) removal and installation

Locate noises from the steering

Remove install bellows

Remove install bellows1

Remove install bottom engine compartment paneling

Remove install electric steering lock (ELV)

Remove install inner tie rod with axial joint

Remove install rack-and-pinion steering

Remove install steering column tube

Remove install steering column tube1

Remove install steering coupling

Remove install steering coupling1

Remove install steering wheel

Remove install track rod

Remove install track rod1

Remove install track rod2

Removing installing drive unit and motor for steering column adjustment

Replacing steering shaft boot

Separate and connect steering coupling

Service Information Play in the rack-and-pinion steering system

Service Information Warranty and goodwill policies for steering wheels

Turning rack-and-pinion steering to center position and fitting steering coupling

Turning rack-and-pinion steering to center position and fitting steering coupling1

Wiring diagram for electric power steering control unit

Wiring diagram for steering column module control unit

47 Fuel system

Electrical function diagram for purging function

Electrical function schematic for system purging with leak test

Empty fill fuel tank

Empty fill fuel tank1

Open, close latch

Remove install activated charcoal canister

Remove install fuel pump control unit

Remove install fuel pump

Remove install fuel tank

Risk of explosion caused by fuel igniting, risk of poisoning caused by inhaling and swallowing

Service information Return delivery of fuel-guiding parts

Service Information Usability of E10 fuel

Wiring diagram for fuel pump control unit

49 Exhaust system

Notes on the disposal of catalytic converters in retrofit systems for diesel particulate reduction

Notes on the disposal of diesel particulate filters

Remove install components for exhaust system

Service Information Care of tail pipe finishers

Service Information Recycling of diesel particulate filters

54 Electrical, equipment and instruments

Assignment of engine fuse and relay module

Assignment of instrument panel fuse box

Assignment of left fuse and relay module

Assignment of prefuse box in vehicle interior

Assignment of rear fuse and relay module

Charge battery

Charge battery1

Charge battery2

Charge battery3

Charge battery4

Check condition of additional battery

Check condition of battery

Check condition of battery1

Connector separation point wiring diagram

Deactivate transport mode prior to vehicle delivery

Deactivate transport mode using key combination

Disconnect connect battery ground line

Disconnect connect battery ground line1

Electrical function schematic for alternator management

Electrical function schematic for comfort function shutoff

Electrical function schematic for DC AC converter

Electrical function schematic for DC AC converter1

Electrical function schematic for dynamic idle speed increase

Electrical function schematic for energy management for engine start stop

Electrical function schematic for no-load current management

Fuse and relay box, as-built configuration

Fuse assignment of prefuse box in engine compartment

Initial filling of battery

Maintaining on-board electrical system voltage when performing test and diagnosis work on vehicle

Notes for 12-V lithium-ion battery

Notes on AGM battery

Notes on battery

Programming of control units

Programming of control units1

Reduce increased voltage after charging process

Remove and install DC AC converter control unit

Remove install 12 Volt socket

Remove install 12V socket of rear center console

Remove install 115V 230V socket

Remove install 360 degree camera control unit

Remove install 360° camera in outside mirror

Remove install 360°front camera

Remove install additional battery relay

Remove install additional battery

Remove install additional battery1

Remove install backup camera

Remove install battery sensor

Remove install battery sensor1

Remove install battery

Remove install battery1

Remove install battery2

Remove install battery3

Remove install battery4

Remove install cigarette lighter

Remove install cockpit clock

Remove install fanfare horns

Remove install front central operating unit

Remove install front prefuse box

Remove install front SAM control unit

Remove install front SAM control unit1

Remove install fuse and relay module in rear

Remove install head-up display

Remove install instrument cluster

Remove install interior compartment prefuse box

Remove install light switch module

Remove install multifunction camera

Remove install park pawl capacitor

Remove install Parktronic system (PTS) control unit

Remove install Parktronic system (PTS) sensors in front bumper

Remove install Parktronic system (PTS) sensors in rear bumper

Remove install pyrofuse electrical connector

Remove install pyrofuse

Remove install radar sensor for driver assistance system in rear bumper

Remove install radar sensors control unit

Remove install rear SAM control unit

Remove install sensors for Blind Spot Assist

Remove install steering column module

Remove install steering column module1

Remove install touchpad control unit

Remove install upper control panel control unit

Remove install voltage dip limiter

Repair supplemental restraint system (SRS) squib wiring harness

Risk of explosion from explosive gas. Risk of poisoning and caustic burns from swallowing battery electrolyte

SCAN coding of control units

Transport safety checklist for starter battery, form

Transport safety checklist for starter battery, form1

Wiring diagram control unit DC AC converter

Wiring diagram for battery charger control unit for high-voltage battery

Wiring diagram for battery management control unit

Wiring diagram for battery management control unit1

Wiring diagram for left fuse and relay box

Wiring diagram for the power electronics control unit

Wiring diagram of engine compartment fuse and relay box

Wiring diagram, engine compartment prefuse box (F32-3)

Wiring diagram, interior prefuse box (F32-4)

Wiring diagram, right dashboard fuse box

Wiring diagram, right dashboard fuse box1

60 Body general

General information on body repair

General information on repair of vehicles with ultra-strength steels.

Product liability, trademark and traffic laws

Service Information brazing materials for MIG brazing

Service Information Handling lead-free filling solder

Service information Measuring and straightening systems

Service Information MIG soldering on structure components and outer paneling

Stamp in vehicle identification number

Vehicle identification number

61 Substructure

Remove install bottom engine compartment paneling

Remove install underbody paneling

62 Front end and fire wall

Install and weld in longitudinal member front section

Install firewall half

Install welding device

Partially install upper front longitudinal member

Partially prepare upper front longitudinal member

Partially remove upper front longitudinal member

Partially replace upper front longitudinal member

Prepare firewall half for installation

Prepare longitudinal member front section

Prepare wheel well for installation

Remove firewall half

Remove wheel well

Remove, install windshield crossmember

Replace complete front end assembly together with reinforcement

Replace left firewall half

Replace longitudinal member front section

Replace suspension strut tower

Replace upper front longitudinal member

Replace upper front longitudinal member1

Separate longitudinal member front section

63 Side wall

Completely replace inner C-pillar side wall

Cut off A-pillar

Cut off B-pillar

Cut off rear wheel well section

Install and weld in B-pillar

Install and weld in complete A-pillar

Install A-pillar outer section

Install C-pillar

Install longitudinal member outer shell on entrance

Install outer rear wheel well

Install rear fender

Install rear fender1

Install rear wheel well section

Partially install side longitudinal member paneling

Partially prepare side longitudinal member paneling

Partially remove side longitudinal member paneling

Partially replace rear wheel well

Partially replace side longitudinal member paneling

Partially replace side longitudinal member paneling1

Prepare A-pillar outer section for installation

Prepare B-pillar for installation

Prepare C-pillar for installation

Prepare C-pillar for installation1

Prepare inner C-pillar side wall.

Prepare longitudinal member outer shell on rocker panel for installation

Prepare outer rear wheel well for installation

Prepare rear wheel well section for installation

Prepare upper front longitudinal member

Preparing complete A-pillar for installation

Preparing new rear fender

Preparing new rear fender1

Remove C-pillar

Remove inner C-pillar side wall.

Remove install A-pillar outer section

Remove install C-pillar

Remove install C-pillar1

Remove install outer rear wheel well

Remove longitudinal member outer shell on entrance

Remove outer rear wheel well

Replace complete A-pillar

Replace complete B-pillar

Replace complete rear fender

Replace complete rear fender1

Replace longitudinal member outer shell on entrance

Separate A-pillar outer section

Separate rear fender

64 Rear wall and rear end

Check water drain in spare wheel well (code 1402P61A47)

Detach rear end

Install crossmember above rear axle

Install rear end

Install rear longitudinal member section

Install rear wall paneling

Install rear wall

Install spare tire well

Left side rear end damage

Partially remove rear longitudinal member

Prepare rear end for installation

Prepare rear longitudinal member section

Prepare rear wall for installation

Prepare rear wall paneling for installation

Prepare spare tire well

Preparing cross member above rear axle for installation

Remove install rear wall paneling

Remove install rear wall

Remove spare tire well

Removing cross member above rear axle

Replace complete rear end

Replace complete rear end1

Replace crossmember above rear axle

Replace spare tire well

Replace spare tire well1

Separate rear wall paneling

Separate rear wall

65 Roof

Notes

Replace complete center roof paneling

67 Windows

Align windshield in body opening

Apply adhesive material

Cut out windows with roll out

Function schematic for electrical rear window heater

Install rear window

Install windshield

Line up rear wall window in the body opening

Notes on removal installation of windshield

Prepare 1-component adhesive cartridge

Prepare body flange for installation of window

Prepare window for installation

Remove install detachable parts when replacing windshield

Remove install detachable parts when replacing windshield1

Remove install rear wall window

Remove install windshield

Replace rubber window spacers

Service Information Stone mark repairs on laminated glass windows

Service Information Change to scope of supply of single-component windshield bonding system

Service Information Windshield, crack formation as result of stone chipping

68 Interior equipment

Adjust inside rearview mirror to steering variant

Adjust inside rearview mirror to steering variant1

Electrical function schematic for roller sun blind

Prepare headliner for installation

Remove install armrest lid on center console

Remove install ashtray housing in front center console

Remove install center console

Remove install center console1

Remove install center console2

Remove install center console3

Remove install cover below instrument panel (left)

Remove install cover below instrument panel (right)

Remove install cover below instrument panel (right)1

Remove install cover for upper control panel control module

Remove install cover for upper control panel control module1

Remove install cover on center console

Remove install cover on center console1

Remove install cover on center console2

Remove install cover on gearshift lever

Remove install cover on stowage box

Remove install cover on stowage box1

Remove install cover on stowage box2

Remove install dashboard

Remove install door sill molding

Remove install door sill molding1

Remove install front floor covering (left)

Remove install front floor covering (right)

Remove install glove compartment

Remove install glove compartment1

Remove install handle on roof

Remove install handle on roof1

Remove install headliner

Remove install inside rearview mirror

Remove install inside rearview mirror1

Remove install lock cylinder on glove compartment lock

Remove install paneling on A-pillar

Remove install paneling on A-pillar1

Remove install paneling on B-pillar

Remove install paneling on rear center section

Remove install paneling on rear center section1

Remove install rear floor covering

Remove install rear shelf

Remove install rear shelf1

Remove install side paneling in rear

Remove install side paneling in trunk

Remove install side paneling in trunk1

Remove install sun visor

Remove install trim at C-pillar

Remove install trim at C-pillar1

Remove install trim strip on dashboard

Remove paneling in trunk

Remove, install roller sun blind

Replace rear cover on center console

Replace rear cover on center console1

Service Information bulletin Surface damage by scent dispenser

72 Doors

Adjust front door

Adjust front door1

Electrical function diagram for power windows

Glue door sealing frame to front door

Rear fuse and relay box wiring diagram

Remove install crank window in front door

Remove install crank window in rear door

Remove install door frame seal on rear door

Remove install door frame seal

Remove install door module

Remove install fixed window in rear door

Remove install front door hinge

Remove install front door hinge1

Remove install front door lining

Remove install front door

Remove install front door1

Remove install front power window switches

Remove install front power window switches1

Remove install rear door hinge

Remove install rear door lining

Remove install rear door lining1

Remove install rear door lining2

Remove install rear door module

Remove install rear door

Remove install sealing for crank window on front door

Remove install sealing for crank window on rear door

Remove install sealing for crank window on rear door1

Remove install switches for rear door power windows

Rework seal on front doors (code 1402P72A49)

Wiring diagram for left front door control unit (DCU)

Wiring diagram for left rear door control unit (DCU)

Wiring diagram for right front door control unit (DCU)

Wiring diagram for right rear door control unit (DCU)

Wiring diagram for trunk lid control unit

77 Sliding roof, soft top - attachments

Adjust front panoramic glass roof

Adjust front panoramic glass roof1

Adjust tilting sliding roof panel

Apply adhesive material to front glass cover

Cut out panoramic roof frame

Electric wiring diagram for panoramic sliding roof

Electrical function schematic for tilting sliding roof (SHD)

Function schematic for electric panoramic sliding roof

Install front glass cover

Prepare front glass cover body flange for installation

Prepare front glass cover for installation

Remove install drive cable for panoramic sunroof roller sun blind

Remove install front glass cover

Remove install front panoramic glass roof

Remove install front panoramic glass roof1

Remove install front panoramic glass roof2

Remove install front panoramic roof roller sun blind

Remove install front panoramic roof roller sun blind1

Remove install glass roof on tilting sliding roof

Remove install guide tube for roller sun blind drive cable

Remove install motor for roller sun blind on panoramic sliding roof

Remove install motor for roller sun blind on panoramic sliding roof1

Remove install paneling on tilting sliding roof

Remove install panoramic roof wind deflector

Remove install panoramic roof

Remove install panoramic sliding roof motor

Remove install panoramic sunroof drive guide rail

Remove install pop-up bracket on tilting sliding roof

Remove install rear panoramic glass roof

Remove install rear panoramic roof roller sun blind

Remove install roller sun blind guide rail

Remove install tilting sliding roof frame

Remove install tilting sliding roof frame1

Remove install tilting sliding roof motor

Remove install tilting sliding roof motor1

Remove install water drain rail for sliding roof

Remove install water drain rail for sliding roof1

Remove install wind deflector

Remove install wind deflector1

Wiring diagram for sliding roof control module

82 Electrical system body

Adjust headlamps

Adjust headlamps1

Adjust headlamps2

Adjust headlamps3

Adjust wiper arms

Automatic interior lights control electrical function schematic

Check function of headlamp range adjustment

Check function of headlamp range adjustment1

Check function of headlamp range adjustment2

Check function of headlamp range adjustment3

Check headlamp adjustment

Check headlamp adjustment1

Check headlamp adjustment2

Check headlamp adjustment3

Check wiper arms and adjust

Check wiper arms and adjust1

Check wiper arms

Cockpit Management and Data System (COMAND) control unit wiring diagram

Cockpit Management and Data System (COMAND) control unit wiring diagram1

Component description for overhead control panel control unit

Electrical function diagram for audio mode, function

Electrical function diagram for Digital Audio Broadcasting, function

Electrical function schematic ambiance illumination

Electrical function schematic for backup light actuation

Electrical function schematic for brake light actuation

Electrical function schematic for cellular phone

Electrical function schematic for driving light actuation

Electrical function schematic for driving light actuation1

Electrical function schematic for emergency alarm

Electrical function schematic for front fog light actuation

Electrical function schematic for hybrid vehicle telematics services function

Electrical function schematic for manual interior lights control

Electrical function schematic for mirror taximeter

Electrical function schematic for navigation system function

Electrical function schematic for SDAR function

Electrical function schematic for speaker system function

Electrical function schematic for spray nozzle hose heater

Electrical function schematic for taximeter

Electrical function schematic for two-way radio hands-free system

Electrical function schematic for two-way radio integration

Electrical function schematic for windshield washer

Electrical function schematic for windshield wiper

Electrical function schematic, headlamp switch-off delay (SWA)

Electrical function schematic, standing light parking lights actuation

Electrical function schematic, turn signal light actuation

Function schematic for Adaptive Highbeam Assist

Function schematic for Intelligent Light System

Injury hazard from pinching and crushing, in extreme cases extremities can even be cut off when caught in windshield wiper

Navigation, function

Notes on avoiding damage to optical fibers during repair work

Notes on avoiding damage to optical fibers during repair work1

Notes on determining headlamp aiming values

Notes on wiper arm adjustment

Notes on wiper arm adjustment1

Overview of system components, telematics

Perform SCN coding of COMAND Audio 20 control unit (code 1405P54B07)

Program Touchpad control unit (code 1403P82A89)

Read out map data release from navigation system, general view

Rear speakers

Removal and installation of loudspeakers in instrument panel Model 140

Remove and install wiper arm

Remove and install wiper arm1

Remove install antenna splitter

Remove install Bluetooth antenna

Remove install COMAND controller unit

Remove install COMAND controller unit1

Remove install communications module stationary heater antenna

Remove install contact plate for cell phone holder (UPCI (UHI)) in the armrest

Remove install control unit for TELE AID emergency call system

Remove install driving lights actuation module

Remove install driving lights actuation module1

Remove install driving lights actuation module2

Remove install driving lights actuation module3

Remove install driving lights actuation module4

Remove install emergency call system antenna

Remove install fan for lamp unit

Remove install front axle level sensors

Remove install global positioning system (GPS) antenna

Remove install headlamp control unit

Remove install headlamp control unit1

Remove install headlamp control unit2

Remove install headlamp control unit3

Remove install headlamp control unit4

Remove install lamp unit

Remove install lamp unit1

Remove install lamp unit2

Remove install lamp unit3

Remove install LED module for front lamp unit

Remove install LED module for front lamp unit1

Remove install LED module for front lamp unit2

Remove install LED module for front lamp unit3

Remove install left footwell bass speaker

Remove install left right rear window antenna amplifier

Remove install license plate lamps

Remove install loudspeaker amplifier control unit

Remove install multimedia connection unit in front stowage compartment

Remove install overhead control panel control unit

Remove install radio display

Remove install rain light sensor

Remove install rear axle level sensor

Remove install right footwell bass speaker

Remove install taillamp

Remove install telematics services communications module control unit

Remove install telephone antenna

Remove install telephone antenna1

Remove install tuner unit

Remove install TV antenna amplifier

Remove install washer fluid reservoir heat exchanger

Remove install washer fluid reservoir heat exchanger1

Remove install washer fluid reservoir of windshield washer system

Remove install washer fluid reservoir of windshield washer system1

Remove install washer fluid reservoir of windshield washer system3

Remove install windshield washer hose

Remove install wiper system

Removing and installing hands-free system speaker

Removing and installing loudspeaker in instrument panel

Removing and installing loudspeakers in front doors

Removing and installing loudspeakers in instrument panel Model 124

Removing and installing loudspeakers in instrument panel

Removing and installing speakers in the rear shelf

Return delivery whereabouts of CDs DVDs and other media, form

Risk of fire and explosion caused by ignition of window washing fluid or antifreeze and their vapors

Search and symbol illumination electrical function schematic

Service information Copy protection in navigation unit with hard-disk navigation

Service Information Bulletin Wiper blades

Service Information COMAND online monitoring

Service information Copy protection in navigation unit with hard-disk navigation

Service Information Feedback on incomplete or faulty map data of the navigationsystem

Service Information Free map updates for COMAND

Service Information Free map updates for COMAND1

Service Information Free map updates for COMAND2

Service Information Note on delivery inspection

Service information Notes on fogged headlamps or lamps in the outer area

Service information Notes on handling SD card navigation Garmin MAP PILOT

Service Information Notes on introduction of Mercedes Connect me

Service Information Repair of damaged Audio COMAND wiring harnesses

Service Information Repair of leaky washer fluid hoses

Service information Return delivery process of customer's own CDs DVDs and other media

Service information Warranty and goodwill policies for wiper blades

Service information Wiping quality and noise development

Sound amplifier control unit wiring diagram

Sound amplifier control unit wiring diagram1

Technical modifications Electric system body Model 140

Technical modifications Electrical system body Model 124

Telephone (TEL) wiring diagram

Telephone (TEL) wiring diagram1

Update map data for navigation system

Windshield washer system - inspect fluid level, adjust to correct level

Windshield washer system - inspect fluid level, adjust to correct level1

Windshield washer system - inspect fluid level, adjust to correct level2

Windshield washer system

Windshield wipers, windshield washer system and headlamp cleaning system - function check

Windshield

Wiper arm

Wiper blade

Wiring diagram for antenna module

Wiring diagram for antenna module1

Wiring diagram for antenna module2

Wiring diagram for antenna module3

Wiring diagram for Audio COMAND display

Wiring diagram for Audio COMAND display1

Wiring diagram for Audio COMAND display2

Wiring diagram for emergency call system control unit

Wiring diagram for emergency call system control unit1

Wiring diagram for emergency call system control unit2

Wiring diagram for emergency call system control unit3

Wiring diagram for Keyless Go control unit

Wiring diagram for telematics services communications module control unit

Wiring diagram for touchpad

Wiring diagram for tuner unit control unit

Wiring diagram for tuner unit control unit1

Wiring diagram for tuner unit control unit2

Wiring diagram interior illumination

Wiring diagram interior illumination1

Wiring diagram of exterior lights

Wiring diagram of exterior lights1

Wiring diagram of exterior lights2

Wiring diagram of exterior lights3

Wiring diagram of exterior lights4

Wiring diagram of exterior lights5

Wiring diagram of exterior lights6

Wiring diagram of exterior lights7

Wiring diagram of MOST bus

Wiring diagram of stationary heater (STH) control module

Wiring diagram, front central operating unit

83 Climate control

Check condensation water drainage hoses for blockages

Disassembling, assembling AC housing

Disassembling, assembling AC housing1

Disassembling, assembling AC housing2

Drain, evacuate and recharge air conditioning, check for proper operation and check for leaks

Drain, evacuate and recharge air conditioning, check for proper operation and check for leaks1

Electrical function schematic for climate control actuation

Electrical function schematic for climate control input signals

Electrical function schematic for preconditioning system

Electrical function schematic for triggering heater booster mode

Electrical function schematic, teach-in of stationary heater radio remote control transmitter

Function schematic for stationary heater (STH) electrical system

Lubricate positioning bracket of air distribution flap (code 1402P83A32)

Notes on handling refrigerant R134a

Procedure for a damaged or leaky air conditioning system

Procedure for a damaged or leaky air conditioning system1

Protect air conditioning circuit and components from moisture when carrying out repair work

Protect air conditioning circuit and components from moisture when carrying out repair work1

Protect air conditioning circuit and components from moisture when carrying out repair work2

Refrigerant compressor, remove install

Remove and install center air vent

Remove and install evaporator temperature sensor

Remove and install heat exchanger

Remove and install heat exchanger1

Remove and install heat exchanger2

Remove and install heat exchanger3

Remove and install left blend air flap actuator motor

Remove and install multifunction sensor

Remove and install right blending air actuator motor

Remove and install Telestart receiver

Remove install actuator motor for flap for fresh air ram air recirculated air

Remove install actuator motor for flap of defroster footwell center air vents

Remove install actuator motor for flap of left footwell center air vents

Remove install actuator motor for flap of right footwell center air vents

Remove install air conditioner housing

Remove install air conditioner housing1

Remove install air conditioner housing2

Remove install air conditioner housing3

Remove install air conditioner housing4

Remove install air conditioner housing5

Remove install air conditioning system control unit

Remove install air outlet temperature sensor, left footwell vent

Remove install air outlet temperature sensor, left side air vent

Remove install air outlet temperature sensor, right footwell vent

Remove install air outlet temperature sensor, right side air vent

Remove install climate control operating unit in rear passenger compartment

Remove install condenser

Remove install defroster vent flap actuator motor for windshield

Remove install desiccant cartridge

Remove install desiccant cartridge1

Remove install evaporator

Remove install expansion valve

Remove install expansion valve1

Remove install expansion valve2

Remove install expansion valve3

Remove install expansion valve5

Remove install front climate control operating unit

Remove install fuel metering pump

Remove install heater unit

Remove install ionizer

Remove install left A-pillar air distribution actuator motor

Remove install perfume generator

Remove install PTC heater booster

Remove install rear passenger compartment center air vent air outlet temperature sensor

Remove install refrigerant pressure sensor

Remove install replace heater circulation pump

Remove install right air nozzle

Remove install right A-pillar air distribution actuator motor

Remove install side air nozzle

Remove install the rear blend air flap actuator motor

Removing and installing blower motor

Removing and installing rear air nozzle

Removing and installing rear air nozzle1

Risk of explosion caused by welding or soldering work on closed air conditioning system

Risk of explosion caused by welding or soldering work on closed air conditioning system1

Service Information AC sealant

Service Information on stationary heater, auxiliary heater, heater booster

Service information Return delivery of interior air filters

Teach in stationary heater radio remote control transmitter

Wiring diagram for electric refrigerant compressor

Wiring diagram for electric refrigerant compressor1

Wiring diagram of automatic air conditioning (AAC) control unit

Wiring diagram of automatic air conditioning (AAC) control unit1

Wiring diagram of automatic air conditioning (AAC) control unit2

Wiring diagram of automatic air conditioning (AAC) control unit3

Wiring diagram of heater booster control unit

Wiring diagram of stationary heater (STH) control module

88 Detachable body components, exterior flaps

Actuate emergency release of fuel filler flap

Adjust engine hood

Adjust front bumper

Adjust trunk lid

Check joint dimensions on trunk lid and rear bumper (code 1402P88A46)

Disassemble assemble front bumper

Disassemble assemble front bumper1

Electrical function schematic for automatic dimming mirror

Electrical function schematic for folding outside mirrors

Electrical function schematic for mirror heater

Electrical function schematic for mirror lens adjustment

Electrical function schematic for passenger-side outside mirror park position

Electrical function schematic for trunk lid control

General information on the impact absorber

General information on the impact absorber1

Remove install complete outside mirror

Remove install engine hood

Remove install fender liner in front fender

Remove install fender liner in rear fender

Remove install folding drive for outside mirror

Remove install front bumper

Remove install front bumper1

Remove install front fenders

Remove install glass adjustment drive

Remove install hood hinge

Remove install longitudinal member paneling

Remove install Mercedes star

Remove install mirror glass

Remove install outside mirror trim

Remove install radiator grille

Remove install rear bumper

Remove install remote trunk closing button

Remove install remote trunk closing control unit

Remove install remote trunk closing drive unit

Remove install tank recess

Remove install trunk lid handle

Remove install trunk lid lock cylinder

Remove install trunk lid

Remove install trunk lid1

Rework sheet metal shackle on front fender (code 1401P88A17)